Rapid prototyping manufacturing, production manufacturing

One-stop Solution, Quality part, Fast service, improve the life

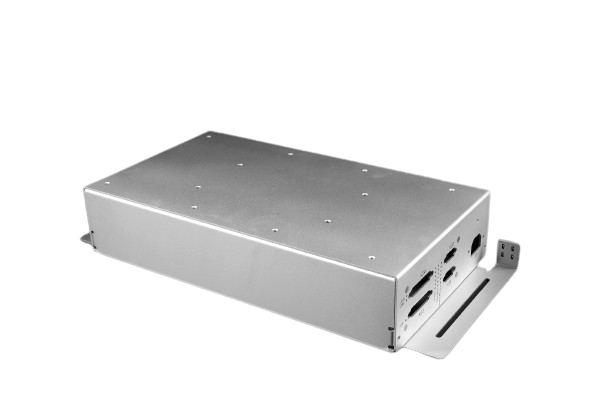

- Sheet Metal

Rapid protyping manufacturing, production manufacturing

One-stop Solution, Quality part, Fast service, improve the life

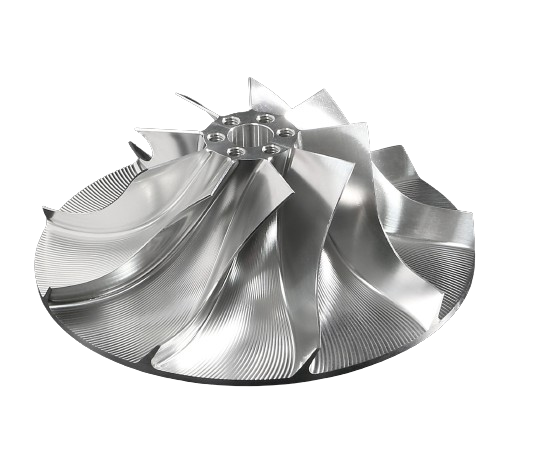

- CNC Machining

Rapid protyping manufacturing, production manufacturing

One-stop Solution, Quality part, Fast service, improve the life

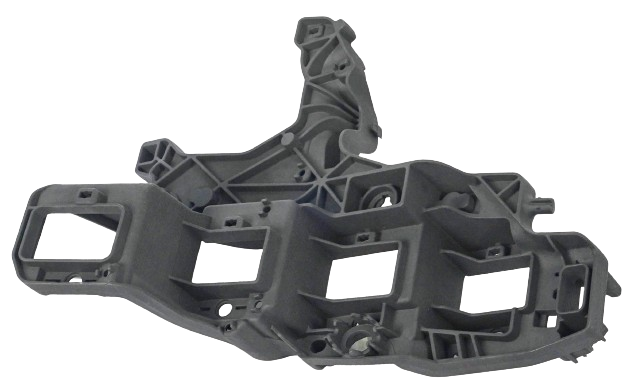

- Injection Molding

Rapid protyping manufacturing, production manufacturing

One-stop Solution, Quality part, Fast service, improve the life

- 3D Printing

ABOUT US

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Sheet Metal Fabrication

From an assortment of cutting tools to different fabrication equipment,we can produce large volumes of fabricated sheet metal.

Injection Molding

High precision,flexibility, low waste,repeatability,repeatability, wide range of different plastics material, and cost efficiency at scale, our custom plastic injection mold use wide arrange in different industry.

CNC Machining

Fast and precision CNC machining through the use of state-of-the-art 3-axis ,4-axis and 5-axis equipment and lathes.

3D printing

Utillzing sets of modern 3D printers and various secondary Processes, we effectively turn your concept into tangible products.

Manufacturing Capabilities

At MY Prototyping, we offer rapid prototypes and on-demand manufacturing services designed to help you stay competitive in a rapidly changing market. Our comprehensive capabilities include professional material selection, an expert tooling process, superior-quality production, and an extensive quality management system.

How MY Prototyping Works

With many years of manufacturing experience, MY Prototyping offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Upload A CAD File

To start, simply select a manufacturing process and upload a 3D CAD file and 2D PDF file.

Get Quote with Solution

Within a few hours we'll send you design for manufacturability analysis and real-time pricing.

Manufacturing & Quaility control

Strickly quality control,100% outgoing QC check before the parts shipments.

Have parts Shipped To You

Safe package keeps parts safe to ship to you. Parts shipped using DHL express or semilar ,by air for common delivery, by sea for mass production

Why MY Prototyping?

Turn your concept into reality through outstanding on-demand manufacturing services. MY prototyping produces simple and complex prototypes and end-use parts with powerful and efficient manufacturing capabilities. All our products meet strict tolerance criteria and quality standards, making us the leading on-demand manufacturing company in China.

Instant Real Factory Quote

-1024x576.jpg)

Powerful Manufacturing Capabilities

24/7 Engineering Support

Testimonials

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements

News Letter

Check out the latest industry trends and get inspired by our updated blog, giving you fresh insights to help grow your business.

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …