Quality, Fast

Customized demands manufacturing

Wide-range solution

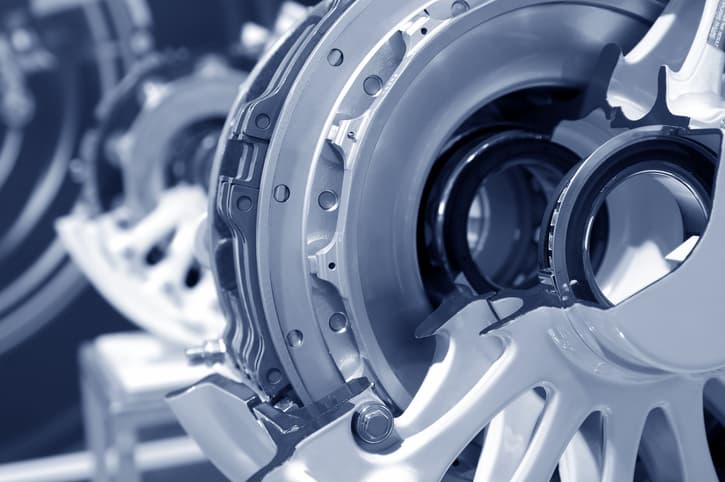

As one of the only companies in the world, we offer such a wide range of in-house rapid prototypes , low-volume manufacturing and massive production one-stop solution. We are committed to turning the good designs and concepts into reality,to change human life, with our proficiency encompasses cutting-edge techniques such as sheet metal fabrication, CNC machining, rapid injection mold, 3D printing and more.

- Home

- Capbilities

Expert Engineering support with Robust Product Quality

Our team of seasoned engineers, boasting over 13 years of combined experience, meticulously reviews and refines design plans. Prioritizing high performance, cost-effectiveness, and manufacturing efficiency for molds, each design document undergoes thorough scrutiny of various factors to guarantee the development of exceptional products and injection molds

Wall Thickness

Stress

Aesthetics

Cost

Shrinkage

Assembly

Dimensional Stability

Manufacturing Services with Industrial Standards

MY prototyping provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm+/- 0.001 inch |

| Hole diameters(not reamed) | +/- 0.025 mm+/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm+/- 0.001 inch |

| Threads and tapped holes | Diameter: Φ 1.5-5 mm, depth: 3×diameterDiameter: Φ 5 mm or more, depth: 4-6×diameter |

| Part size limit | 4000×1500×600 mm157.5×59.1×23.6 in. |

At MY prototyping, we provide various injection molding services tailored to meet your manufacturing requirements. Our plastic injection mold types including rapid tooling, family molds, multi-cavity molds, 2K injection mold, Insert-molding,over-molding and so on. We adhere to different manufacturing standards for each service.

| Standard | Description |

| Maximum Part Size | 1200×1000×500 mm47.2×39.4×19.7 in. |

| Minimum Part Size | 1×1×1 mm0.039×0.039×0.039 in. |

| Part to Part Repeatability | +/- 0.1 mm+/- 0.0039 in. |

| Mold Cavity Tolerances | +/- 0.05 mm+/- 0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

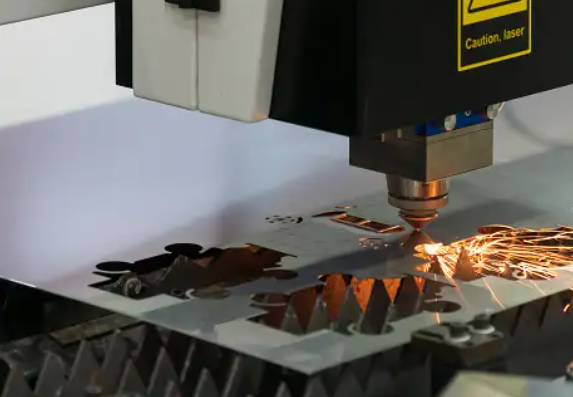

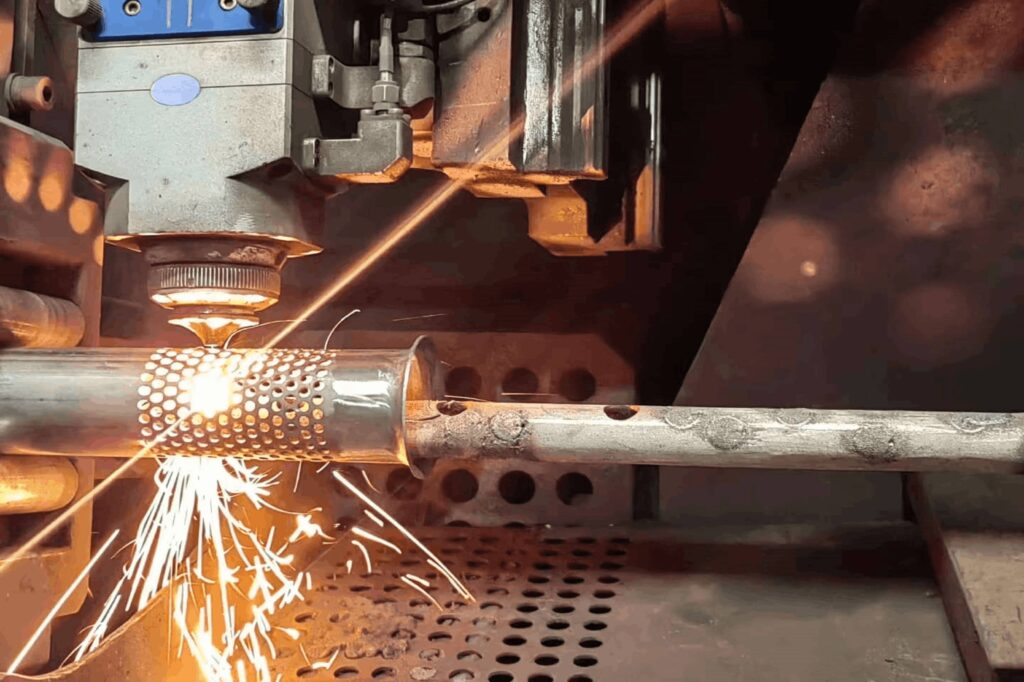

We have the experience and expertise in sheet metal fabrication to bring your ideas to life. Our services include high-tolerance laser cutting, plasma cutting, bending capabilities, and post-processing options.

| Dimension detail | Tolerance |

| Edge to edge, single surface | +/- 0.005 inch |

| Edge to hole, single surface | +/- 0.005 inch |

| Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface | +/- 0.030 inch |

| Over formed part, multiple surface | +/- 0.030 inch |

| Bend angle | +/- 1° |

Our vacuum casting service uses silicone molds to produce production-grade elastomeric parts with 10-200 units.

| Typical lead time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

| Accurate | ± 0.3% (with lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

| Minimum wall thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum part dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Typical quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

| Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |

We maintain a high standard for our engineering team and equipment to consistently deliver robust and durable parts and prototypes. Our strict die casting process guarantees that your custom requirements are met, ensuring exceptional quality.

| Dimension | Standards |

| Minimum part weight | 0.017 kg |

| Maximum part weight | 12 kg |

| Minimum part size | ∅ 17 mm × 4 mm |

| Maximum part size | 300 mm × 650 mm |

| Minimum wall thickness | 0.8 mm |

| Maximum wall thickness | 12.7 mm |

| Tolerance class for casting | ISO 8062 ST5 |

| Minimum possible batch | 1000 pcs |

Custom Manufacturing On Demand

Along with our strong manufacturing capabilities, we also provide you the design impact on the cost, the ability to choose the manufacturing volume and other processes that match your production needs, and the best competitive surface finishing solution.

Rapid prototypes

We use the latest technology and equipment to produce prototypes quickly and accurately, helping clients to reduce their product development time and costs.costs.

Capability: 20-500

MOQ: 1PC

Low volume production

For batch manufacturing, we have several options to accommodate your requirements, like vacuum casting, CNC machining, and plastic injection molding.

Capacity: 500-1000

MOQ: 1PC

Massive Volume manufacturing

To complete large-volume manufacturing requirements, take advantage of our plastic injection molding, sheet metal fabrication, and other production processes.

Capacity: 1000+

MOQ: 1PC

Quality Control Can be Witnessed Everywhere

MY prototyping takes pride in our strict quality control standards applied throughout each section of our production process. Our expert quality auditors pay close attention to detail, inspecting each product for inconsistencies.

IS0 9001:2015 Certified

We hold the ISO 9001:2015 certification, which stands as evidence of our unwavering commitment to quality.

Well-vetted Suppliers

Close partnerships with thousands of reliable material suppliers guarantee constant access to quality materials.

Rigorous Quality System

Our strict commitment to quality control regulations ensures consistent quality is maintained throughout production.

Strict Manufacturing Standard

We uphold established manufacturing standards, such as ISO 2768-fine and ISO 2768-medium.

Advanced Testing Facilities

Completed prototypes go through various testing machines, like profile projectors, CMM, and 3D scanners.

Complete Quality Report

Get comprehensive quality reports from our in-house quality team or third-party labs.

Human Support, Beyond the Transaction

Our commitment extends beyond order completion – we offer exceptional support, empowering you to confidently introduce your products to the market. Backed by over a decade of industry experience and extensive product knowledge, our expert technicians assist you with troubleshooting and optimizing product use.