News

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

- Home

- News

Related Posts

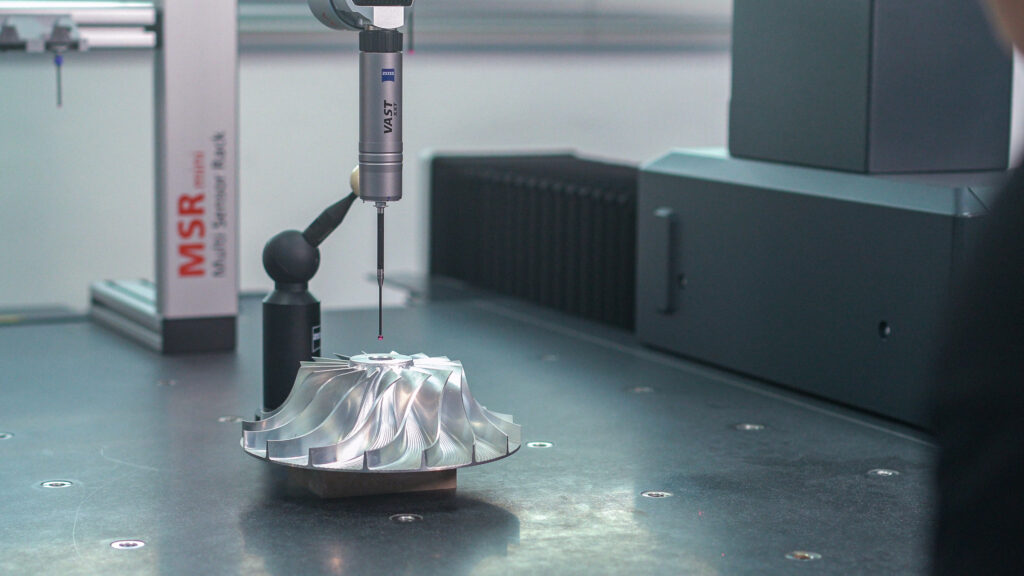

Modern industries such as architecture, engineering, and manufacturing rely on computer programs to create designs of various parts and prototypes.Therefore, understanding ‘what is g code’ becomes essential for anyone involved in the field of Computer Numerical Control (CNC), 3D printing, or any other computer programming language for designing machined parts.This article will have an in-depth discussion on what is G-code, its usage, how it works, different types of G-code commands, and many other helpful information. What is G-Code? G-code is a type of programming language used in computer numerical control (CNC) and 3D printing to instruct machine tools to move. It is written in Computer Aided Manufacturing (CAM) software to provide automation instructions for various machine functions and tools.G-code stands for geometric code. G-codes are also known as preparatory codes for CNC machines.The instructions provided by G codes tell the machine tool how to move in the (X, Y, Z) Cartesian coordinate system.In addition to location instructions, the G code also provides many other inputs such as speed and angle in the rotary axis, tool length offset, start point, stop point, feed rate, dwell time, etc.G codes work in conjunction with M codes. M codes stand for machine codes or

All CNC machines rely on G-code for their operation. Contrary to what some people believe, G-code for CNC machine is not a difficult concept. It is very easy to understand the basics of G-code, how it works, and how to create a G-code for your next project. Read on to find out everything there is to know about G-code for CNC machines. What is G-Code? G-code is a type of CNC programming language used to control the functions of a CNC machine that relate to the movement of the cutting tool.It stands for Geometric Code. G-code consists of instructions that the microcontroller in the CNC machine can read and interpret. The instructions are then sent to the appropriate part of the machine. A single line of G-code can contain several instructions. Each line of G-code is defined as a block. It is a very simple programming language that does not require complex logic or mathematical skills.G-code programming works in conjunction with M-code. M-code stands for machine code and is considered by some to stand for miscellaneous codes. The M code controls the various functions of the CNC machine that are not directly related to motion. These functions include instructions such