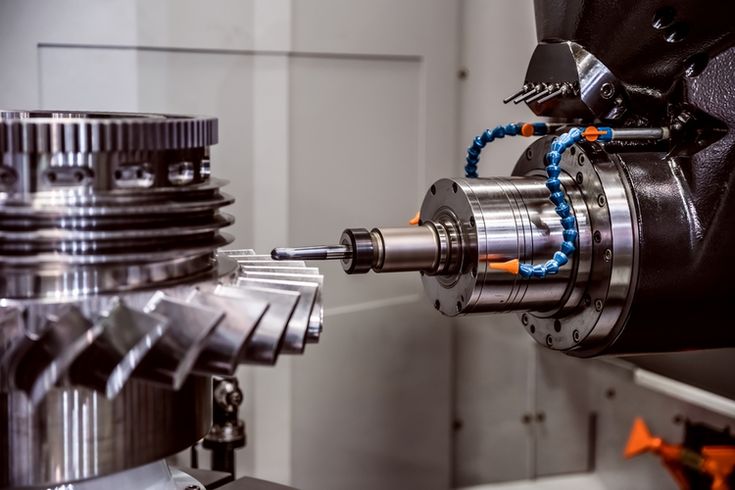

CNC Milling Services

Explore on-demand CNC milling services for rapid prototypes and production parts. Obtain custom milled parts from a variety of high-quality metals and plastics.

Tight Tolerance of 0.01 mm

Milled Parts as Fast as 1 Day

3, 4, 5 Axis Milling

10s

Instant Quotes

1 pc

MOQ

7/24

Engineer Service

99.5%

On time Delivery

14+

Years in Business

MY Prototyping 3 to 5-Axis CNC Milling Service

Experience precision and versatility with our 3 to 5-axis CNC milling service at MYprototyping. Whether it’s fundamental 3-axis milling or complex 5-axis projects, we bring your designs to life with unparalleled accuracy and craftsmanship.

3 Axis CNC Milling

Achieve precision with affordability through our 3-axis CNC milling service at MYprototyping. Ideal for crafting simple parts that demand accuracy, this option provides a cost-effective solution without compromising on precision.

4 Axis CNC Milling

Unleash the possibilities of your designs with MY Prototyping's 4-axis CNC milling. From intricate details to multi-sided machining, we bring your visions to life with enhanced capabilities.

5 Axis CNC Milling

Elevate your designs with MY Prototyping's 5-axis CNC milling. From complex geometries to intricate details, we unlock the full potential of your projects.

Online quote for CNC Milling

Upload drawings on our website.

You will get a fast quotation within 24-48 Hrs.

You could talk to our expert for drawings analysis.

Start a project today!

Precision CNC Milling Solutions: From Concept to Completion

Embark on a journey with MY Prototyping’s CNC milling services, guiding you from your initial idea to the flawless production of your final product. Experience precision and care at every step of the way.

Swiftly transform your CAD designs into impeccably CNC-milled prototypes with MY Prototyping. Test and refine your concepts, minimize milling errors, and expedite your product's time-to-market.

Effortlessly transition from prototype to CNC milling production with MY Prototyping’s Bridge Production. Ensure seamless transition phases, mitigate risks of scaling, and maintain consistent quality throughout.

Meet market demands with precision CNC milling on-demand. MY Prototyping ensures you meet deadlines, manage inventory efficiently, and produce high-quality components exactly when needed.

Order Process

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Instant Quote

To start, simply select a manufacturing process and upload a 3D CAD file.

Order Evaluation and Processing

CAD confirmation and optimization

No Minimum Order Quantity

Flexible order quantities from 1 to 10,000

Production

Fast, precise, and professional manufacturing for your product

Quality Control and Delivery

100% outgoing QC check. Parts shipped using DHL Express or similar.

Materials for CNC Milling Parts

MY Prototyping’s CNC milling service provides a diverse range of materials, ensuring precision and durability. This extensive selection empowers our clients with optimal choices for their unique projects, enhancing their product’s quality and performance.

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

plastic

Plastics are a popular choice for CNC machining due to their versatility, cost-effectiveness, and faster machining times. Explore our CNC machining services with a variety of common plastics available.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

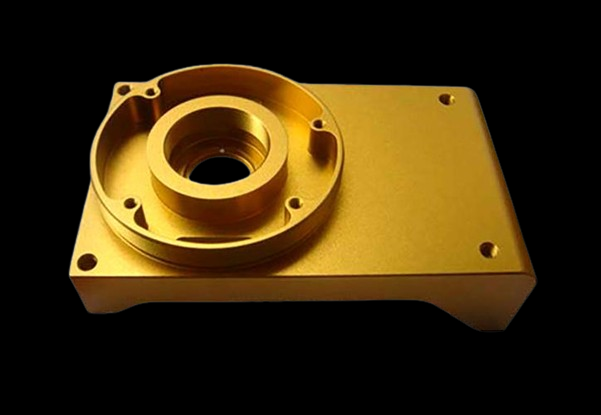

Surface Finishes for CNC Milling

MY Prototyping offers quality surface finishing for custom CNC milled parts, eliminating aesthetic flaws and enhancing the appearance of your products. Our surface finishes also provide robust protection, additional resistance, and strength to your parts, ensuring superior quality.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| PowderCoating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

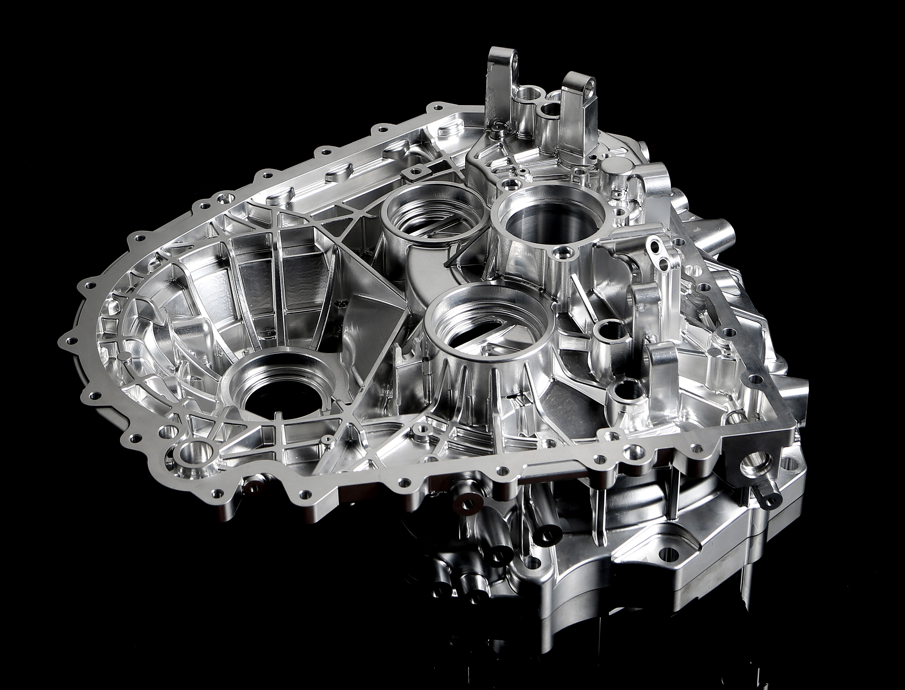

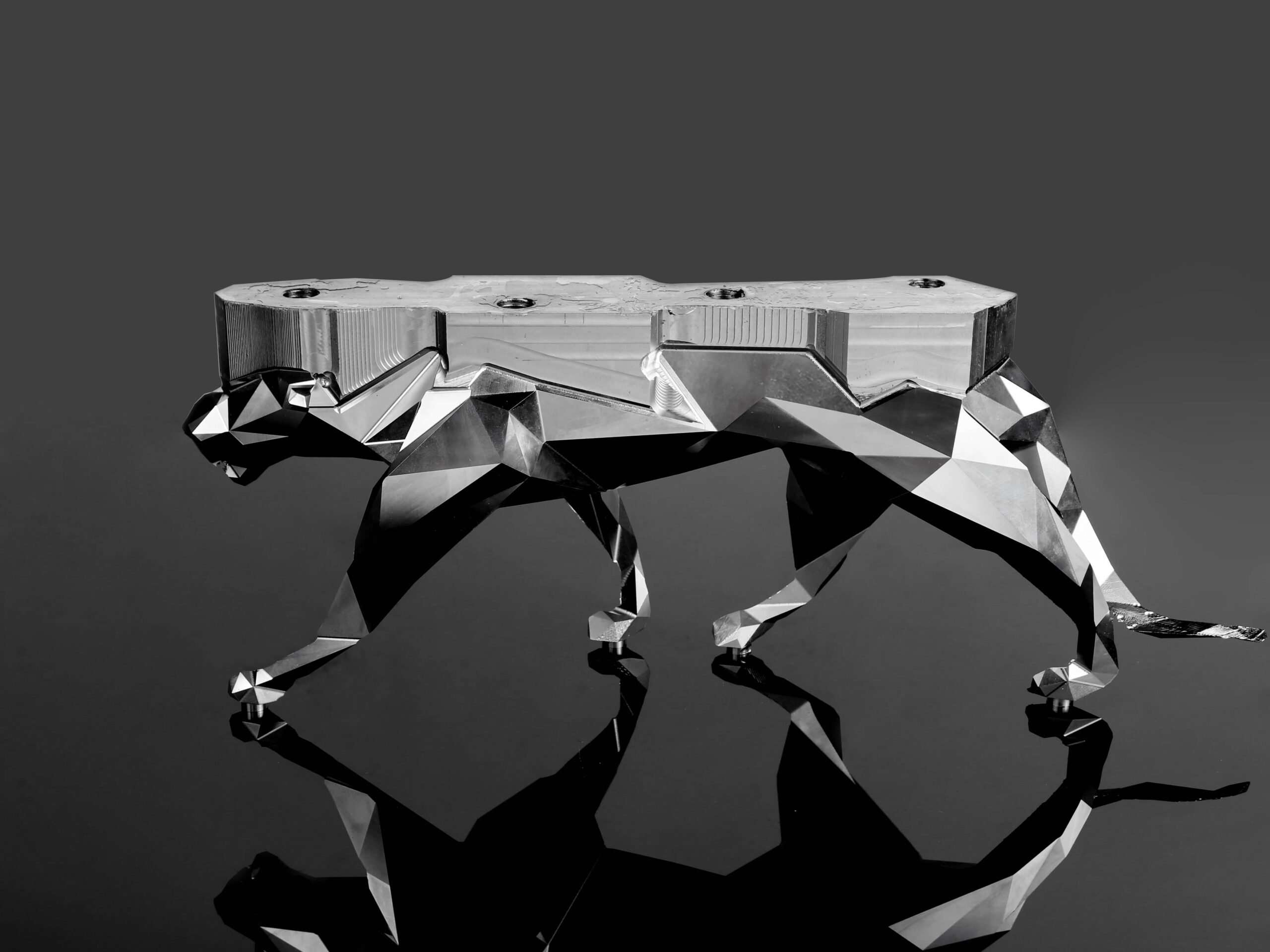

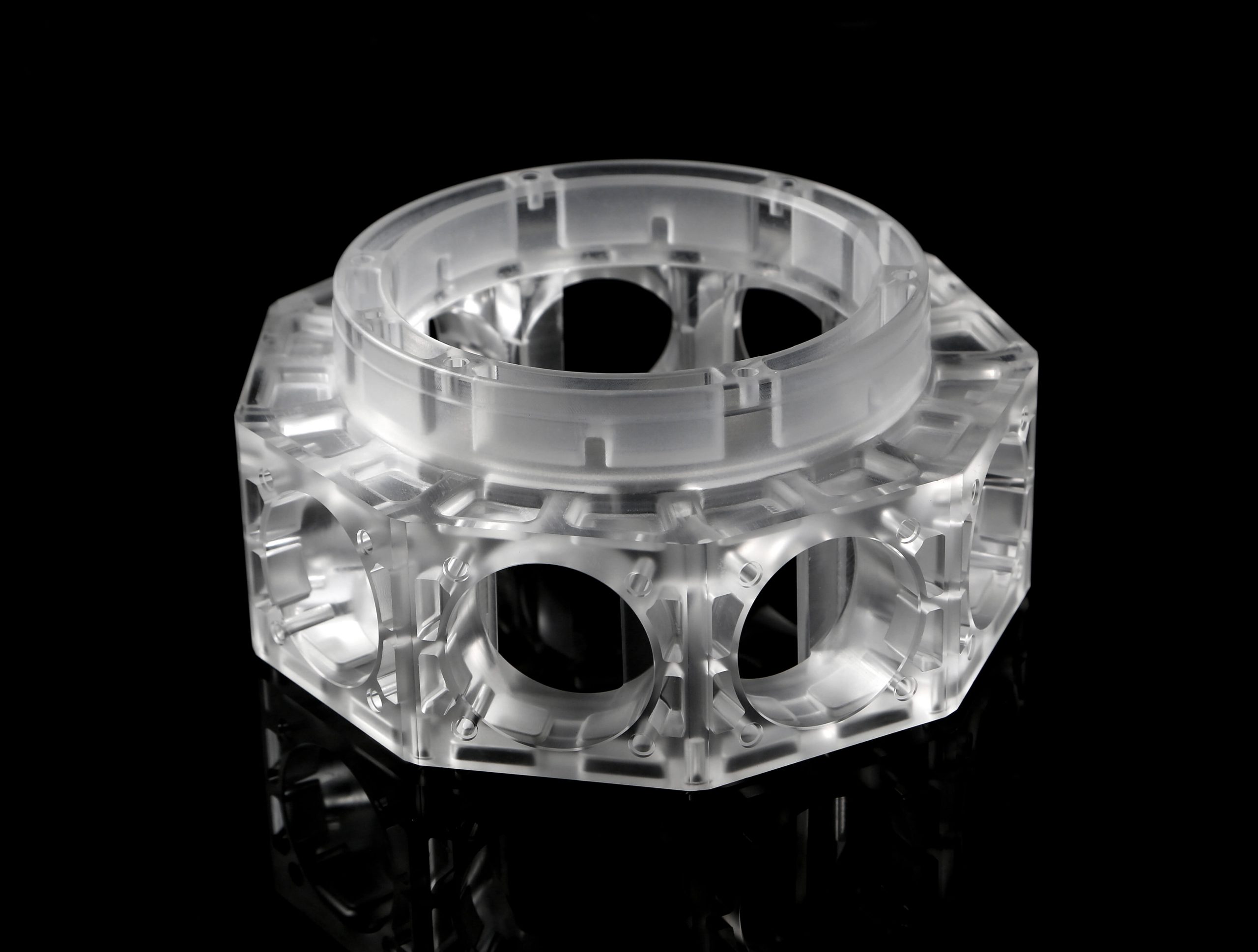

CNC Machining Case Study

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Why Choose MY Prototyping for CNC Milling Service

When you choose MY Prototyping for CNC milling, you’re not just getting access to cutting-edge machinery; you’re investing in unparalleled precision, strict adherence to tight schedules, and the support of seasoned professionals.

Instant Quote

get instant CNC quotes by simply uploading your design files. Our digital quoting analyzes service your part geometry, and provides real-time & competitive pricing feedback.

Consistent High Quality

Rely on our advanced CNC capabilities, stringent quality checks, and continuous communication to guarantee that each machined piece you receive consistently meets the highest standards, ensuring reliability in every project.

Fast and Reliable Delivery

Benefit from our robust manufacturing capacity at MY Prototyping, ensuring swift turnaround for CNC machined parts. Our diverse shipping options further guarantee on-time delivery, eliminating typical hassles in the process.

Professional Engineering Support

Wherever you are, access our 24/7 engineering support year-round. Our seasoned engineers are ready to offer the most suitable solutions for your part design, material selection, surface finishing, and lead time considerations.

Our CNC Machining For Various Industrial Application

MY Prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.