Rapid prototypes, low-volume, high-volume production

Consumer Goods Industry

Experience excellence in consumer product manufacturing with MY Prototyping. Our dedicated services cater to various applications, ensuring high-quality consumer goods and automotive components. Enjoy competitive prices and rapid lead times for all your manufacturing needs.

Instant pricing & free feedback

ISO 9001:2015 certiified

24/7 engineering support

Why Choose MY Prototyping for Consumer Products

Experience unmatched speed and efficiency with MY Prototyping for consumer product prototyping and production. Our dynamic on-demand manufacturing approach ensures swift responses to evolving consumer demands, delivering high-quality manufactured parts and products within a short timeframe. Trust our team of seasoned engineers and experts to offer optimal solutions and expert design modifications, guaranteeing exceptional end results for your consumer product ventures.

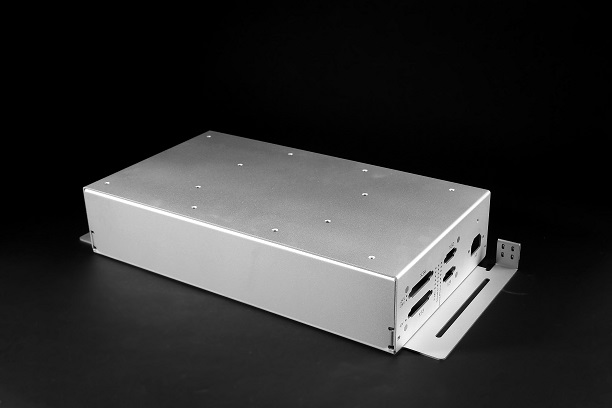

Powerful Capabilities:

Explore the pinnacle of manufacturing prowess with our powerful capabilities at MY Prototyping. Armed with cutting-edge equipment, a highly skilled workforce, and an unwavering commitment to quality, we effortlessly tackle even the most intricate projects. Whether you seek mass production or bespoke solutions, our capabilities ensure the delivery of high-quality products that surpass your expectations.

Instant Quotation:

Experience precision in pricing with our innovative instant quotation system. A few clicks are all it takes to receive a detailed and transparent price estimate for your project. Our system factors in material costs, lead time, and quantity, providing you with a precise and reliable quote. Benefit from free Design for Manufacturability analysis feedback for seamless design iterations.

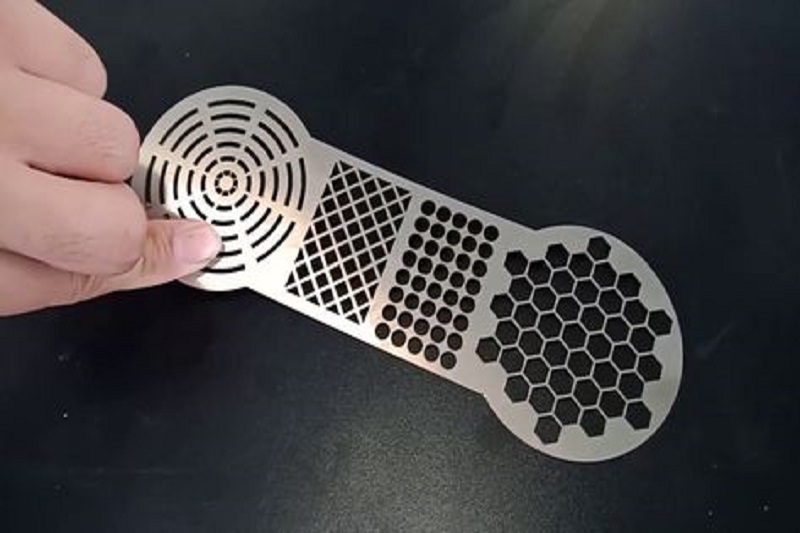

High Precision Parts:

Harness the potential of advanced manufacturing techniques and cutting-edge technology to produce intricate and precise parts. At MY Prototyping, our rigorous quality control processes guarantee that every consumer product meets the highest standards of precision and performance.

Fast Cycle Time:

Pride in promptness – MY Prototyping ensures fast cycle times that position you ahead of the competition. Our streamlined processes prioritize efficiency without compromising quality or accuracy. Propel your ideas to market swiftly with instant quotes and a remarkable reduction in cycle time by up to 50%.

Plastic injection plastic parts for consume industry

At MY prototyping, manufacture plastic injection parts for the consumer industry involves precision and efficiency. These components play a crucial role in various consumer products, ensuring durability and functionality. Our expertise in crafting high-quality plastic parts contributes to the seamless production of items that enhance the daily lives of consumers.

Trusted by Fortune 500 Companies

Consumer electronics companies

Personal and household products manufacturers

Food packaging companies

Appliance manufacturers

Beverage and alcohol companies

Toy producing firms

Athletics equipment manufacturers

Applications of Consumer Products

Explore a new era of personalized consumer products, where uniqueness meets functionality. MY Prototyping’s advanced manufacturing delivers custom designs, varied color options, and diverse materials, providing a competitive edge. Redefine your lifestyle with tailor-made excellence.

Electronic devices

Athletics and sporting equipment

Wearable devices

Virtual reality products

Personal wellness products

Cookware products

Accessory components

Home Furnishings

Smart home products

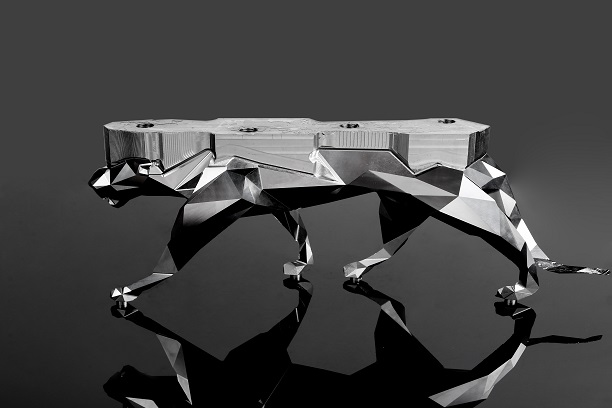

Custom Parts for Customer Industry

Tailor-made components for your industry needs. From intricate designs to flawless execution, experience precision and reliability. Enhance your projects with MY Prototyping’s commitment to excellence in the Customer Industry.

Explore Related Resources

Start a new project production today!

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

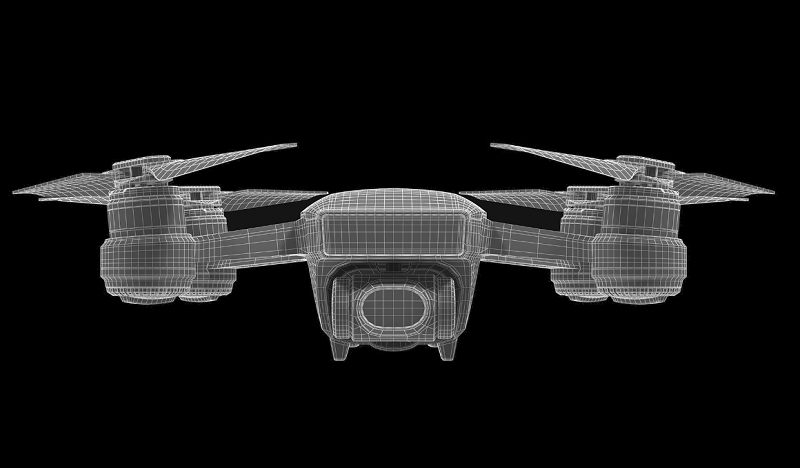

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …