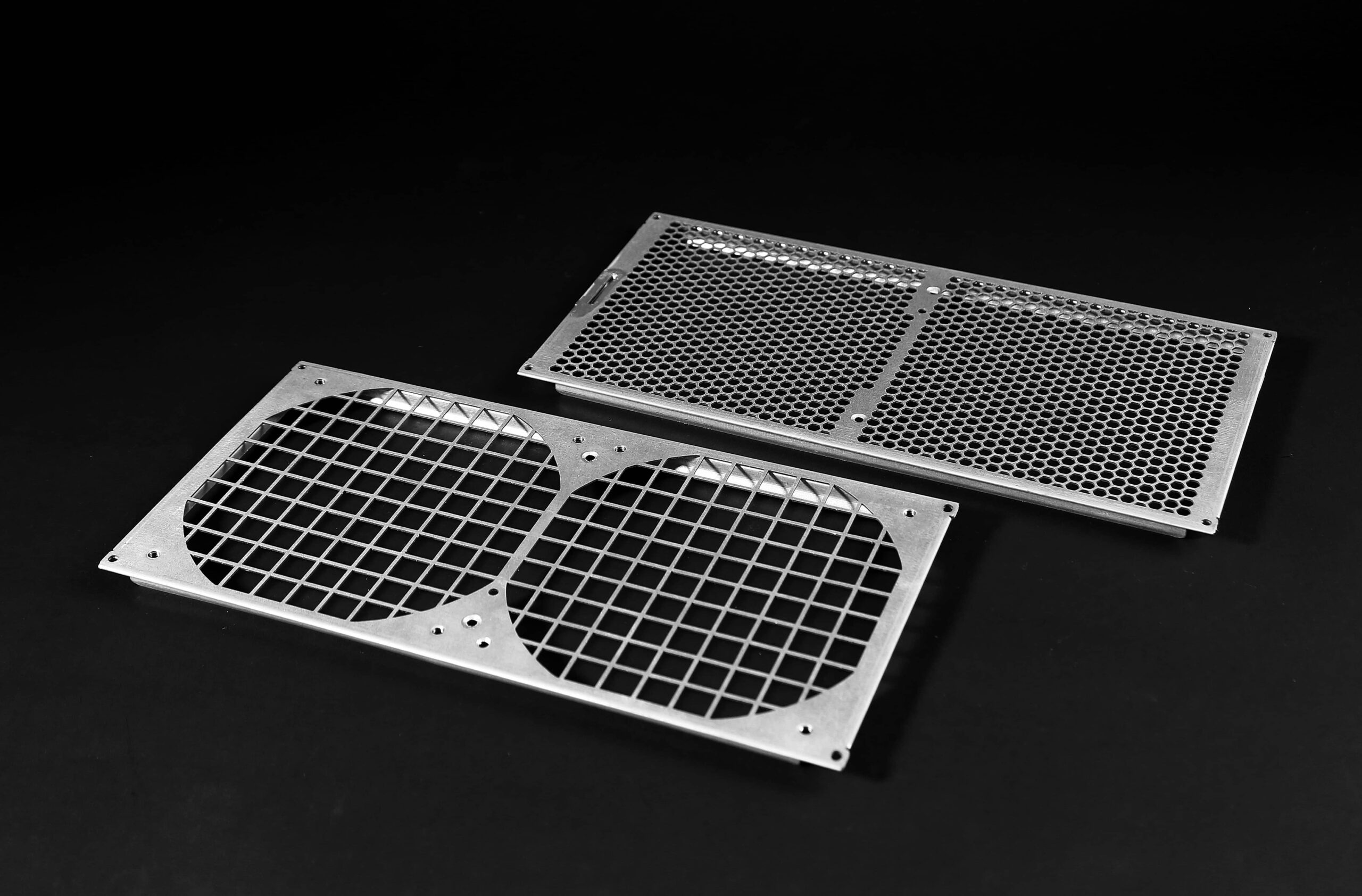

Sheet Metal Materials

Aluminum

Aluminum with its lightweight yet robust nature, offers enhanced durability without excess weight. Its superior malleability allows precise shaping, ideal for intricate designs.

AL5052

AL5083

AL6061

AL6063

Copper

Copper’s advantages are clear: unparalleled electrical conductivity, thermal efficiency, and natural resistance to corrosion, ensuring longevity and performance in fabrications.

CU1020

CU1100

CU2100

CU2200

CU2300

CU2400

CU2600

Brass

Opt for brass to ensure precise machining, a distinct appearance, and efficient heat conductivity, providing advantages for both practical and decorative applications.

C27400

C28000

Stainless Steel

Renowned for its durability and resistance to staining, stainless steel ensures longevity and maintains its appearance, even in harsh environments.

301 303 304

316

420 430

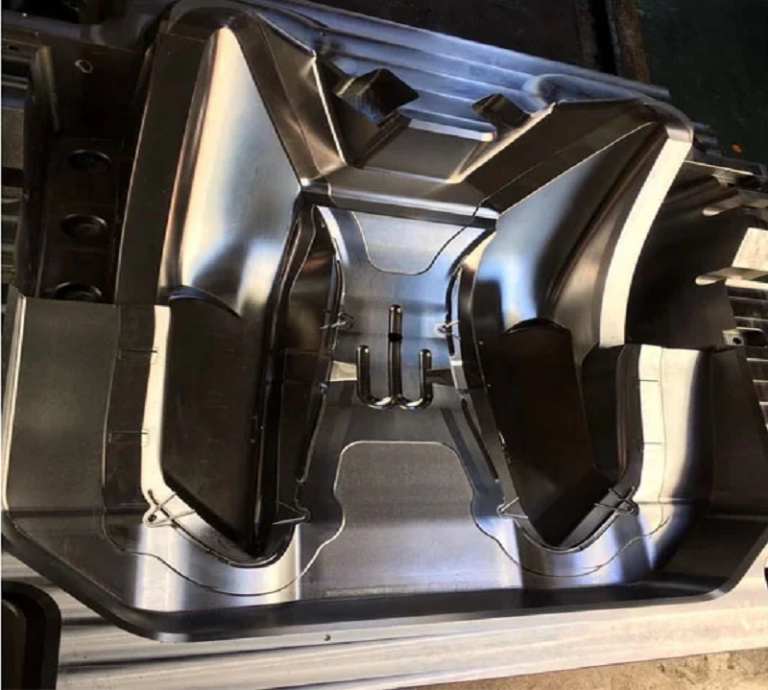

Injection Mold Materials

Tooling Materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

ABS HDPE LDPE PP

PPA PS POM PC

PU Teflon (PTFE) Nylon

PC PMMA PA PEEK

PET

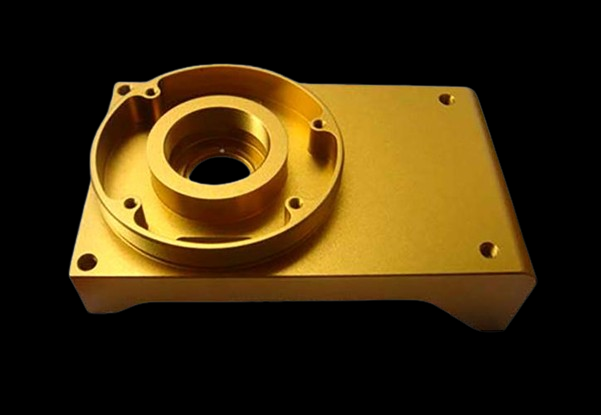

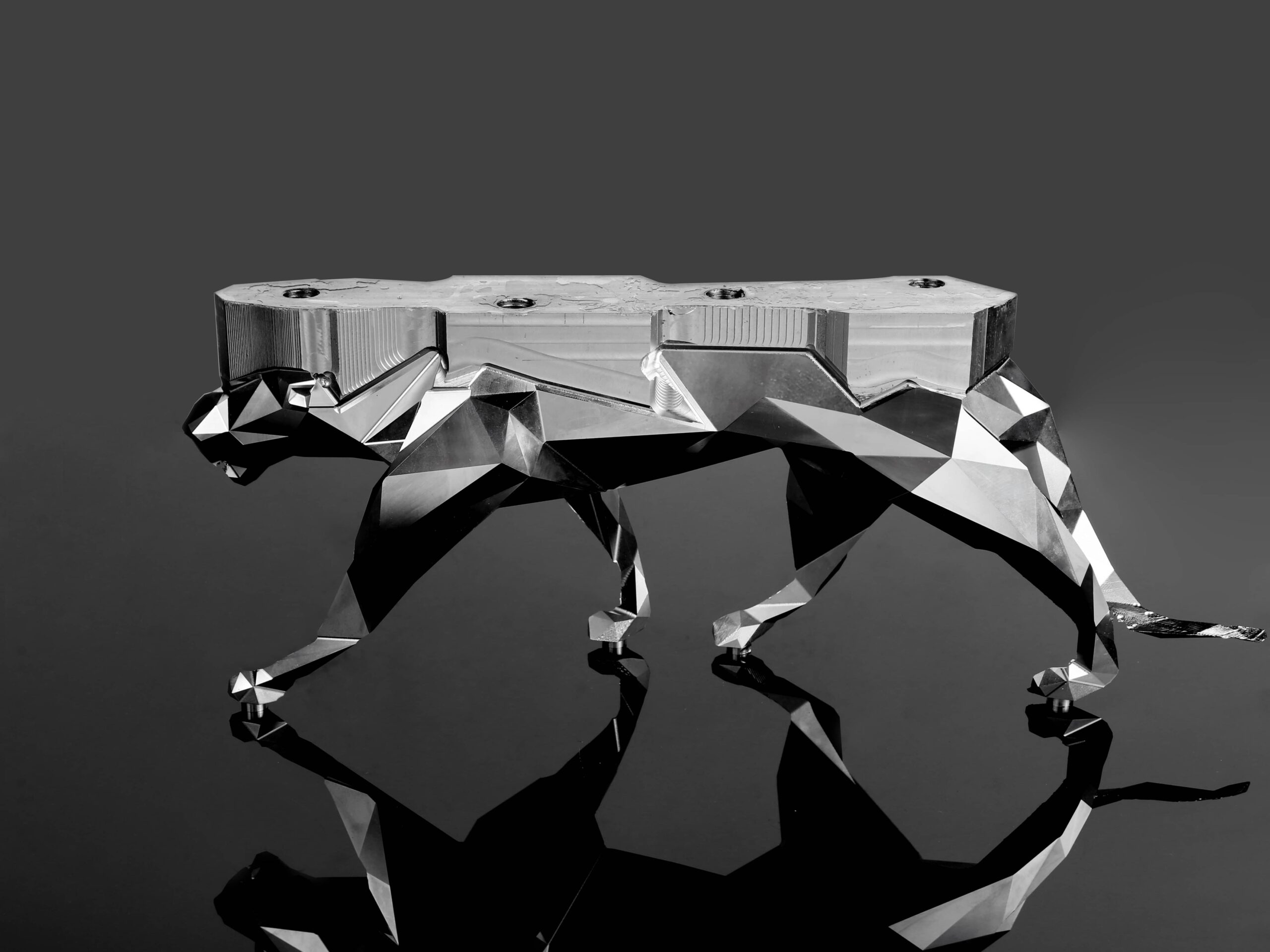

CNC Machining Materials

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastic

Plastics are a popular choice for CNC machining due to their versatility, cost-effectiveness, and faster machining times. Explore our CNC machining services with a variety of common plastics available.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

3D Printing Materials

ABS and Resins

Renowned for its strength, durability, and elevated temperature resistance, ABS stands out as a premier selection for 3D printing. Suited for functional prototypes and intricate designs, ABS guarantees dependable performance and a remarkable finish.

Technology: SLA

Color: White, Beige, Black, Red, Semi-transparent

Types:

– ABS Photosensitive Resin

– High Temperature Resistant 70°C Photosensitive Resin

– Black Toughness 70°C Heat-Resistant Photosensitive Resin

– Semi-Transparent – Photosensitive Resin

White Tough Resin

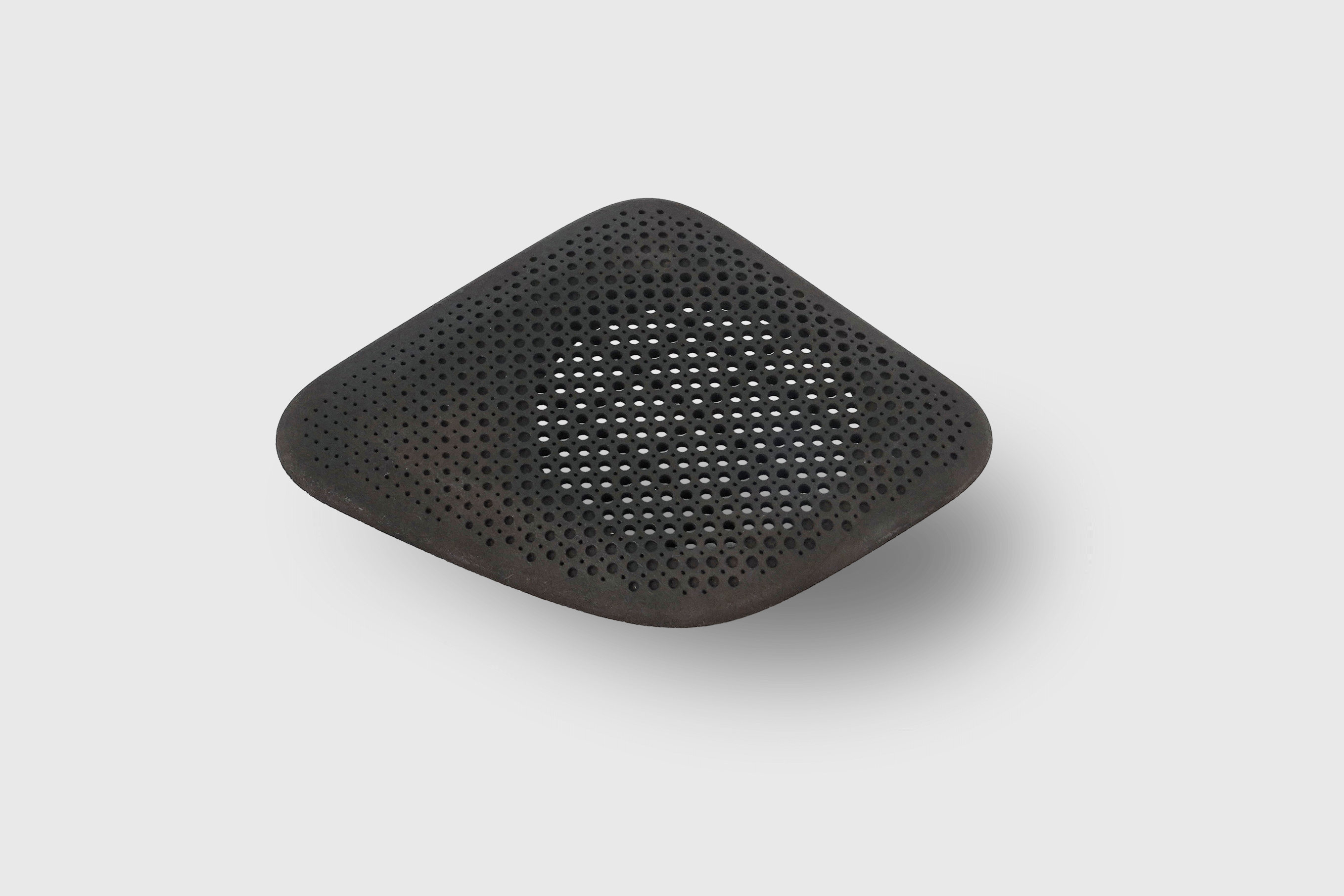

PA (Nylon)

Possessing outstanding strength, flexibility, and resistance to abrasion, Nylon emerges as an optimal choice for small quantities of prototypes and resilient end-use products. Its enduring durability and adaptability guarantee a high standard of quality in long-lasting prints.

Technology: MJF, SLS

Color: Original color, gray-black,

black painted

Types: HP Nylon

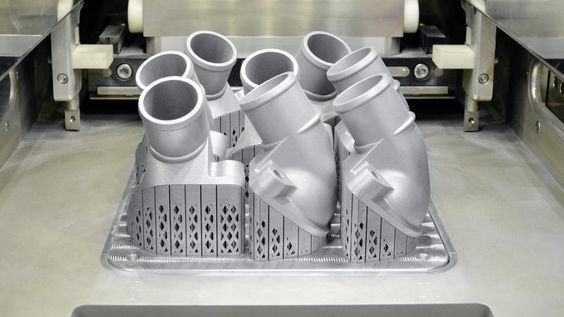

Aluminum

Aluminum metal 3D printing presents a distinctive combination of lightness and strength, coupled with exceptional thermal conductivity and resistance to corrosion. This renders it a premier choice for creating high-precision, durable prints.

Technology: SLM

Color: Silvery Gray

Type: ALSI10MG Aluminum Alloy

Stainless Steel

With unparalleled strength, resistance to corrosion and heat, and durability, stainless steel proves to be an ideal choice for industrial 3D applications. It guarantees the production of high-quality, precise parts endowed with excellent mechanical properties.

Technology: SLM

Color: Gray-black

Type: 316L ,in 718L Stainless Steel

Titanium

With exceptional strength, resistance to corrosion and heat, and impressive durability, titanium stands out as an excellent option for a wide range of industrial applications. It guarantees the creation of precise, high-quality components with outstanding mechanical properties.

Technology: DMLS

Color: Gray-black

Type: Ti15-45

Start a new project production today!

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …