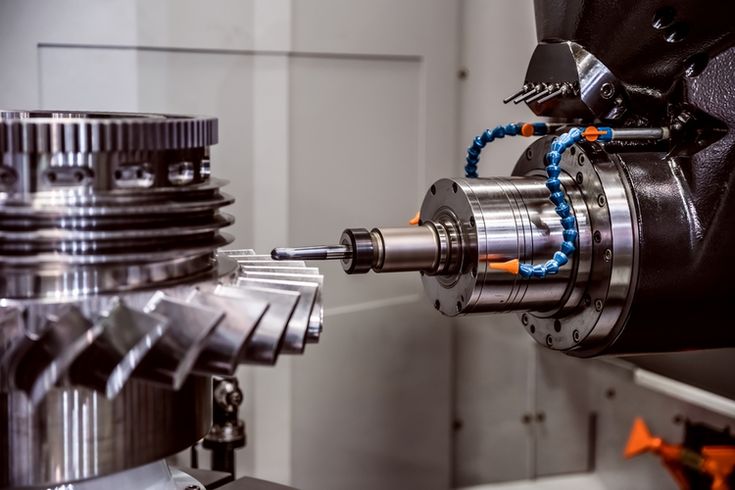

CNC machining fulfills the need for a wide variety of services. For this purpose, CNC machines are available in many different versions. Among these options, 3-axis CNC, 4-axis CNC, and 5-axis CNC machining are the most common options.Professionals often wonder about the best choice between 3 vs 4 vs 5 axis CNC machining. This article will discuss in detail the differences between these three machining processes. You will also learn about the capabilities of each method.

Differences Between 3-Axis, 4-Axis and 5-Axis CNC Machining

3-axis, 4-axis, and 5-axis CNC machines use the same basic technology. However, there are significant differences in their capabilities.

·Axes of movement: The axes of motion are the primary differentiating factor between 3-axis, 4-axis, and 5-axis CNC machining. The degree of axes is the direction in which a cutting tool can move. Therefore, 5-axis CNC machining has the highest degree of cutting tool motion.

·Part Complexity: Higher-axis CNC machines can design more complex parts. This is because the cutting tool can reach more difficult angles.

·Positioning: Higher-axis machines offer more positioning options. Therefore, 5-axis machines provide the most positioning options. 4-axis machines have moderate positioning capabilities. 3-axis CNC machines are the most limited in terms of positioning.

·Programming: 5-axis machines require a complex program. The program will control the movement of the cutting tool in multiple directions. 5-axis machines have many more variables in this regard. 3-axis CNC machines have the simplest programs. 4-Axis CNC is a balance between the two.

·Time: 5-axis machines take the least time to complete a part. 3-axis machines take the longest. The faster speed of 5-axis machines is due to the fact that multiple cutting tools are working on the part at the same time. The time taken by a 4-axis CNC is greater than 5-axis, but less than 3-axis.

·Operator Training: 5-axis and 4-axis CNC machines require highly skilled operators due to the complex machine setup. 3-axis CNC machines can work with the low skill level of the operator. Highly skilled operators in 5-axis CNC machines also increase the operator’s salary. Operators with low skills can use a 5-axis CNC. However, they cannot use the full potential of the machine.

·Customization: 5-axis machines can provide a higher degree of customization. This is because the cutting tool has more freedom of movement. The part can be modified in any way. 3-axis machines are not as friendly to customization. These machines require the part to be repositioned for customization.

·Material Management: Some materials are difficult to machine. Using 3-axis machining can accelerate tool wear. Using 4-axis or 5-axis machining is easier for these materials. These machines can approach the workpiece in a way that reduces tool wear and makes machining easier.

·Tool Breakage: Multi-axis machines, such as the 4-axis and 5-axis machines, provide more options in the approach position and angle of the tool. This allows a shorter tool to be used. This increases accuracy and reduces tool breakage. In 3-axis CNC machining, the tool approaches the workpiece perpendicularly. This increases tool breakage in 3-axis CNC machining.

·Tool Collision: 5-axis machines require complex programming. Any small error can cause the tool to collide with the workpiece. Tool collision is less pronounced on 3-axis and 4-axis machines. Tool collision can be eliminated by using advanced simulation capabilities of CAM software.

·Secondary Finishing: 5-axis machines provide a very smooth finish to the part due to their high accuracy. However, 3-axis and 4-axis machining often requires secondary finishing to improve the workpiece surface.

·Error Accumulation: 3-axis machines can only machine a single side of the part. Therefore, multiple setups are required. Each setup introduces a certain amount of error, which accumulates with additional setups. However, 4-axis and 5-axis machines can produce precision parts in a single position. Therefore, there is no error accumulation.

What is a 3-axis CNC?

3-axis CNC machining can move the cutting tool in three directions. These directions are the X axis, Y axis, and Z axis. 3-axis CNC machines are the most basic CNC machines. The direction of movement is:

·X axis: Left to right movement of the cutting tool in the horizontal plane.

·Y axis: Up and down movement of the cutting tool in the horizontal plane.

·Z axis: Vertical movement of cutting tool

Advantages of 3-axis CNC machining

·Cheaper: 3-axis CNC machines are significantly less expensive than higher-axis alternatives.

·Ease of use: It is very easy to learn to use 3-axis CNC machines. It doesn’t require complex operator training.

·Simple Programming: 3-axis CNC requires simple programming. Simple changes in the program can make all the changes in the part.

·Low Maintenance: These machines require less maintenance due to the simple structure of the machine.

Disadvantages of 3-Axis CNC Machining

·Slower Manufacturing: 3-axis CNC machining is faster than other manufacturing methods. However, it is significantly slower than higher-axis CNC machining.

·Capabilities: 3-axis CNC machines cannot produce parts with complex geometries.

·Slower Production Speed: 3-axis CNC often requires parts to be realigned for complete machining. This reduces production speed in the manufacturing process.

·Single-Side Machining: 3-axis CNCs can only machine one side during a single setup.

·Low Accuracy: Using multiple setups limits the accuracy that can be achieved with a 3-axis CNC.

When Should You Use a 3-axis CNC Machine?

3-axis CNC machines are best suited for the following applications:

·Lower Budget: 3-axis CNCs are the machine of choice for limited budget situations. These machines have lower capital and maintenance costs.

·Low Production Volume: Low-volume production benefits from 3-axis CNCs. These machines are simple and easy to set up. In addition, the low cost of the machine reduces the overall production investment.

·Simple Structure: 3-axis CNC is good when parts have simple geometry. These parts should have basic shapes without complex features.

What is 4-axis machining?

4-axis CNC machining adds a rotary axis to the basic three axes. Therefore, these machines have a fourth axis in addition to the X, Y, and Z axes. It is called the A axis. It is the axis of rotation along the X axis.

Advantages of 4-Axis CNC

·Multi-Side Machining: 4-axis CNC can work on four sides of the workpiece in a single setup. This eliminates the need for multiple setups.

·Cheaper Higher volume machining: 4-axis machines offer a lower total cost of ownership for high-volume production. This is because fewer setups are required compared to 3-axis CNCs.

High accuracy: The reduction in setups means that tight tolerances can be achieved.

Disadvantages of 4-axis CNC

·High Machine cost: 4-axis CNCs have a higher machine cost than the 3-axis alternative.

·Expensive Fixtures: Fixtures on a 4-axis CNC may not be economical for basic machining on a single face.

·Limited Speed: 4-axis CNC is slower than higher-axis alternatives.

When to use 4-axis CNC?

4-axis CNC machines are suitable for applications such as

·Curved Surface features: 4-axis CNC machining can machine curved surface features. It is also ideal for angled features. The angled features should be based on one axis only.

·High Tolerance: 4-axis CNC is a good choice for situations that require higher accuracy than what 3-axis CNC can provide. This is due to the reduced number of setups on these machines.

·Machining Multi-sides: 4-axis CNC machining is good when working on a part with features on multiple sides.

·High High-volume production: High volume production can efficiently use 4-axis CNC machining.

What is 5-axis CNC machining?

5-axis CNC machining tools have two rotary axes and three axes in linear directions. The three linear directions are

·X axis: Left to right movement horizontally across the work table

·Y axis: Up and down movement horizontally across the table

·Z axis: Vertical movement of cutting tools

In addition, the rotary axes can be any two of the following three axes

·A axis: Rotary motion along the X axis

·B axis: Rotary motion along the Y axis

·C axis: Rotary motion along the Z axis

Advantages of 5-axis CNC

·Complex Geometries: 5-axis CNC machining is capable of machining highly complex geometries of a workpiece.

·Machinable Sides: It is possible to machine five different sides of a part in a single setup.

·High Speed: The reduced number of setups allows for extremely high production speeds.

·Precision: 5-axis CNC machining can produce precision parts. Single-setup machining eliminates any variation when changing setups.

Disadvantages of 5-axis CNC

·Costs: 5-axis CNC machines are very expensive compared to 3-axis and 4-axis CNC options. There are also additional maintenance and operating costs.

·Operator Training: 5-axis CNC machines can be complicated to operate. Therefore, the operator needs special skills and training.

·Programming: 5-axis CNC programs are complex due to the addition of two variables.

When Should You Choose 5-axis CNC Machining?

5-axis CNC machines are ideal for the following situations:

·Complex Shapes: 5-axis CNC machining is the ideal choice for machining complex shapes.

·High Volume: High production volumes are handled very well with these machines. It can reduce the cost per part for high volumes.

·Precison Parts: Precision parts for industries such as R&D, aerospace and medical parts require 5-axis machining.

·Multi Side Machining: Parts with features on each side require 5-axis machining.

How do I choose between 3-axis, 4-axis and 5-axis machines?

Choosing between 3-axis, 4-axis and 5-axis machining can be easier if you know the factors to consider. Here are the things to evaluate when deciding between these methods:

·Cost: Cost is the most important factor for most manufacturers. For people on a budget, 3-axis machining is definitely the way to go. You can only consider 4 and 5 axis CNC machining if budget is not an issue.

·Application: Aerospace parts, medical parts, defense equipment, aircraft parts, dental implants and other such applications require ultra-high precision. These precision parts can only be produced with multi-axis machining such as 5-axis.

·Part Shape: Parts with a simple shape are suitable for 3-axis machining. You can save costs by choosing 3-axis machining for such parts. However, using 3-axis for complex geometries will result in additional costs and defects. In such cases, 4-axis or 5-axis machining is a better choice. The choice between the two can be made based on the part geometry.

·Machining Process: If you already have a CNC machine, the choice of number of axes may be limited. For example, vertical milling machines are usually only capable of 3-axis movement. A milling machine with a rotary table is a 4-axis machine. Similarly, there are CNC milling machines with 5-axis configurations.

·Production Volume: Select the number of axes based on the production volume you need to manufacture. Low-volume production can be accomplished with a 3-axis machining process. However, high-volume production requires multi-axis options.

End Notes

3-axis, 4-axis and 5-axis CNC machines are designed for a specific group of users. Each of these machines is available at a specific price point and with specific applications. With the information provided above, you can now easily choose between these three options for your next project.

Frequently Asked Questions (FAQs)

Here are answers to some common questions about 3-axis, 4-axis and 5-axis CNC machining:

1. How does the number of axes affect the accuracy of the final product?

A higher number of axes means a higher precision of the final product. This is because multi-axis machining requires fewer workpiece setups. This increases the accuracy during the machining process.

2. How does the number of axes affect the range of materials that can be machined?

A higher number of axes increases the range of materials supported for CNC machining. Multi-axis machines can approach the hard-to-machine material at a more convenient angle. This provides easier machining options for hard materials.

Disclaimer of Warranty

The contents of this website are for informational purposes only. MY Prototyping makes no representations or warranties of any kind, express or implied, as to the accuracy, completeness or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be supplied by third party suppliers or manufacturers through MY Prototyping’s network. Buyers seeking instant quotes for parts are responsible for defining the specific requirements for those parts. Please see our Terms and Conditions for more information.