It’s amazing how 3D printing additive manufacturing and subtractive manufacturing processes drive all global industries! All manufacturing processes fall into one of these two categories. Both have their applications, advantages, and disadvantages. These factors are best understood by comparing additive and subtractive manufacturing processes side by side. Understanding the ins and outs of these processes can help you make the right choice for your project. This will save you time and resources, and give you the best results.

This article is here to help you with that. It compares additive and subtractive manufacturing processes in detail. After reading this article, you’ll be able to make an informed decision about which process to choose.

The basic idea behind additive manufacturing is that it adds materials to create the shape you need. On the other hand, subtractive manufacturing processes remove material from the workpiece. This can be done in lots of different ways, including friction, erosion, heat, or sharp tooling.

So, in additive manufacturing, you start with nothing and end up with the final part. Isn’t that fascinating? But in subtractive manufacturing, you start with a big piece of the workpiece and then carefully remove material to reach the final product. Isn’t that fascinating?

Compare Additive vs. Subtractive Manufacturing

Additive manufacturing and subtractive manufacturing differ in every parameter that matters. Let’s dive into their performance in each of these parameters. Additive manufacturing processes are pretty good at keeping material wastage to a minimum. These processes work by adding material instead of removing it.

Subtractive manufacturing processes, on the other hand, tend to be a bit more wasteful. These processes chip away a lot of material to create the final product. In some cases, the removed material is non-recyclable.

• Additive Manufacturing: Unfortunately, additive manufacturing processes don’t always have the best accuracy. This is because adding material isn’t as controlled as removing material. Additionally, the material expands uncontrollably on cooling, reducing accuracy further.

• Subtractive Manufacturing: On the bright side, subtractive manufacturing processes are generally highly precise. This is because of the controlled machining processes and small cutting tools.

Supported Materials

Both additive and subtractive manufacturing processes cannot manufacture every material. Each of these processes has materials they can work with, but they have their limitations.

• Additive Manufacturing: Additive manufacturing processes are limited in terms of material selection. They work on a few plastics and metals only. Materials like wood cannot undergo additive manufacturing processes.

• Subtractive Manufacturing: Subtractive manufacturing techniques work on all possible materials out there. Even materials like wood and glass can undergo many subtractive manufacturing techniques. Complex shapes are a bit more tricky to work with than the standard set of shapes like spheres, cubes, and cuboids.

• Additive Manufacturing: Additive manufacturing processes can create complex shapes, but they do require a mold of the shape in question.

Let’s talk about manufacturing closed hollow parts!

Production volume

It’s important to remember that a manufacturing process that’s great for small-scale production might not be the best fit for large production runs. Additive and subtractive manufacturing processes have different performances in varying production runs.

Multi-axis CNC machining is a great option for those looking to produce parts at a very high speed.

Manufacturing Speed

A higher manufacturing speed means a lower time taken to manufacture each part. This can provide a higher production volume in a given time, which is great for those looking to get more done in less time!

However, the process can have some lead time, making it better for larger production runs. It is also faster when manufacturing bigger parts.

Surface Finishes

Surface finishing during manufacturing can eliminate the need for secondary finishing processes. This saves cost and time in the overall production time for parts, which is great! Subtractive manufacturing provides a smooth finish to the surface, which is great! Plus, processes like CNC machining can give multiple finishing options, which is really handy.

Operator Skill

It’s important to consider operator skill when comparing the two manufacturing techniques. Some processes require highly skilled operators, which can be tough or expensive to execute. Subtractive manufacturing processes use heavy machinery like CNC machining, so they require skilled operators.

• Subtractive Manufacturing: Subtractive manufacturing processes have a high degree of customization, which is great for making products that are just right for the customer. Simple modifications in the program can achieve any customization, so there’s plenty of room for creativity.

Safety: The safety of the manufacturing process is essential for the workforce, so it’s important to focus on the manufacturing process’s safety protocol, especially for beginners or inexperienced professionals.

• Additive Manufacturing: Additive manufacturing processes are relatively safer because they do not work with any sharp tools, which is great for keeping the workplace safe and healthy. However, they can release toxic fumes when working with plastics, so it’s important to be aware of that and take the necessary precautions.

• Subtractive Manufacturing: Safety is super important when it comes to subtractive manufacturing processes! These machines have sharp tools that can easily pierce the body, so it’s crucial to have detailed safety instructions in place when operating this machinery.

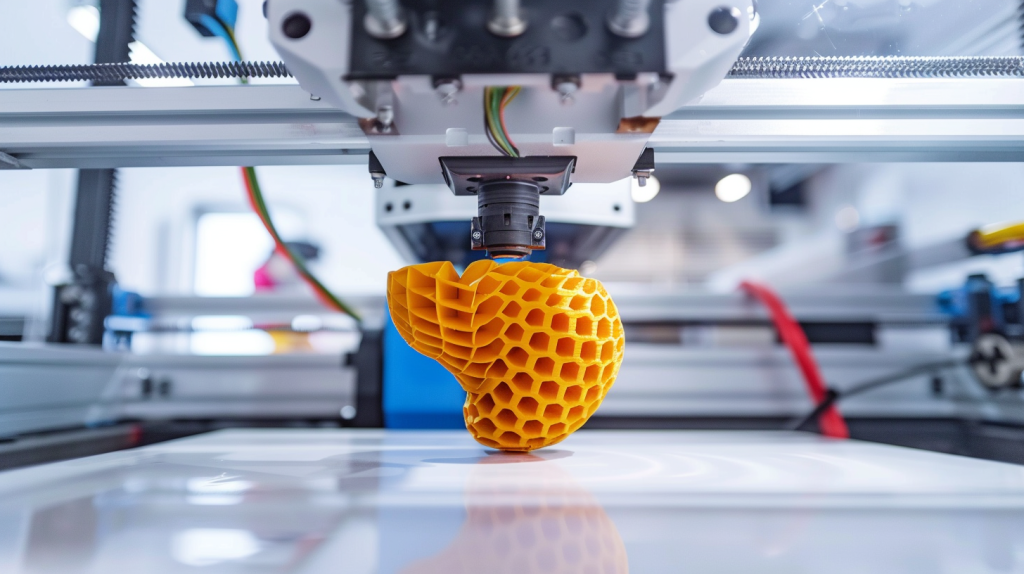

What is additive manufacturing?

Well, it’s a process where parts are created by depositing materials. The material is initially present as a filament, resin, or granules. It is heated and turned into the required part through various processes. Additive manufacturing is a simple and straightforward way to make things. There are lots of different techniques for doing this, and they’re all pretty easy to use.

• Material Extrusion

• Powder Bed Fusion

• Direct Energy Deposition

• Binder Jetting

• Sheet Lamination

• Material Jetting

• VAT Polymerization

• Direct Metal Laser Sintering

• Stereolith Let’s dive into the world of additive manufacturing!

There are so many different techniques out there, and each one has its own unique set of advantages and disadvantages.

Let’s dive in and explore each one together!

Advantages:

• Reduced Wastage: These processes are all about reducing material waste, which is a big win for the planet!

• Reduced Tooling: Tooling costs are pretty low, which is great for your budget.

• On-demand Production: This process can meet your on-demand production goals.

• Lead Times: The lead time in additive manufacturing is pretty short, which is ideal for fast-paced businesses.

• Sustainability: The lower material wastage makes additive manufacturing a sustainable process.

• Customization: One of the great things about processes like 3D printing is that they provide a good room for customization.

• Range of Materials: These processes support many different materials like metals, plastics, and ceramics. There are still many materials that they cannot use, like hardwood, but that’s ok!

• Complex Parts: Additive manufacturing can create complex parts and internal features such as vents.

Disadvantages

• Surface Finishes: There are many surface defects on parts made with these processes. Secondary finishing is almost always required, but that’s ok too!

• Production Volume: These processes aren’t really suitable for mass production.

• Quality Control: There’s not much quality control, and things don’t always come out the same way twice.

• Material Limitation: There are lots of materials that can’t be used with additive processes. Anything that doesn’t melt easily is tricky to work with. That means that the material selection is mainly limited to thermoplastics and some metals.

When to Use Additive Manufacturing?

Additive manufacturing is a great choice for making small parts in small batches. It’s also great for making parts with internal geometry. For instance, additive manufacturing can create parts with cooling vents built in. Additive manufacturing machines like 3D printing are perfect for small-size prototyping processes.

What is the subtractive manufacturing process?

The subtractive manufacturing process means removing material to make something. It starts with a large chunk and removes material through controlled machining. The initial material can be a solid block, cylinder, sheet, or other shapes.

Common Subtractive Manufacturing Techniques

There are so many different subtractive manufacturing technologies used in different scales across the manufacturing sectors! Some common subtractive processes are:

• CNC Lathe

• Laser Cutting Tool

• Waterjet Cutting Tool

• Drilling

• Electrical Discharge Machining

• Grinding

• Reaming

Advantages and Disadvantages of Subtractive Manufacturing

Subtractive manufacturing is great at what it does! There can be minor disadvantages to the process as well. Let’s dive into the pros and cons together!

Advantages of Subtractive Manufacturing

• High Accuracy: Subtractive manufacturing has very high precision. This is great for any requirement where precision is important!

• Computer Numerical Control (CNC): All subtractive processes can use computer numerical control. This amazing technology automates the entire working process of the particular technology.

• Surface Finish: CNC machining leads to a highly smooth surface finish. This is perfect for products that don’t require secondary finishing.

• Complexity: Subtractive manufacturing can create parts with very intricate designs. For instance, CNC machining can do wood carving.

• Speed: These techniques create parts at a very high speed. There is no need to wait for cooling since materials aren’t melted.

• Customization: Any changes in design can be made with small adjustments to the CAD software.

• Errors: CAD software simulation can also check the presence of errors in the designing or programming phase.

• Versatility: These techniques can work on any material, no matter what it’s made of.

• Secondary Processing: These techniques don’t require any extra work after they’re done. This saves time and money.

• Modifications: Subtractive manufacturing can make changes to an existing part. This can be really helpful if you need to repair something.

Disadvantages

• Wastage: The main disadvantage of these processes is that they create a lot of waste. This is especially true when you’re making a lot of parts at once.

• Cost: The cost of subtractive manufacturing equipment is quite a bit more than additive. This makes it less suitable for small-volume production.

There are a few other things to consider, too.

These processes use a lot of electricity, so they’re not the best choice for the environment.

When to Use Subtractive Manufacturing?

Subtractive manufacturing is a great fit when precision and consistency are a concern. This includes sectors such as automotive and consumer electronics. In addition, components that require high finishing also use subtractive processes.

• Type of Material: Think about the type of material your part requires. The material can make it easy for you to decide between additive vs. subtractive manufacturing. For thermoplastics, additive manufacturing can be cost-saving. For metals and alloys, subtractive processes provide better results.

• Production Volume: Subtractive manufacturing is better for large production runs. Additive manufacturing is cost-saving for smaller batches.

• Sustainability: If you want to minimize waste, additive manufacturing is better. If you’re willing to make a few compromises in terms of sustainability, subtractive manufacturing can provide better results.

• Accuracy: For high precision, go with subtractive manufacturing technologies.

• Operator Training: If you have a low-skilled workforce, additive processes can be easy. If training isn’t an issue, subtractive will work well.

• Cost: Additive processes are cost-saving for small parts in small batches. Subtractive processing provides the lowest cost for larger pieces and high volumes.

• Part Design: If your part has a lot of intricate details, subtractive manufacturing might be a better choice. But if your part has internal features like cooling vents, additive processing is a better option.

Cost of Additive vs Subtractive Manufacturing

There are many different costs associated with additive and subtractive manufacturing processes. Here is a breakdown of these costs:

• Equipment: Subtractive machines are more expensive than additive manufacturing machining. However, tooling costs are higher for additive processes than for subtractive ones.

Material: The material costs are higher for additive processes. This is because additive technologies use specialized materials that can undergo heating, which adds to the cost.

Secondary Processing: Secondary processing costs are higher for additive manufacturing. This is because the subtractive process can provide a smooth surface finish to the part, which is a nice bonus.

Labor: Both additive and subtractive processes come with automated controls. Therefore, the labor costs for each process are usually the same. An important point to note is that the automation capabilities of CNC are better than additive options. This is because CNC machines can operate in multiple axes, which is great for making sure everything runs smoothly.

• Electricity: Both additive and subtractive manufacturing machines run on electricity, but subtractive machines use more of it, which means higher energy costs.

• Waste disposal: Subtractive processes have the added cost of waste disposal, which can be tricky to manage. Some of it can be recycled, but disposal costs are still attached. Both of these technologies have their uses and shortcomings, so it’s important to choose the right one for your needs. At MY Prototyping, we can help you decide which technology would be better for your project. We offer on-demand manufacturing and prototyping services in each of these areas, and our experts are always happy to answer any questions you may have about additive vs. subtractive manufacturing processes.

We’ve got your back with these answers to some common questions regarding additive and subtractive manufacturing.

Is additive manufacturing better for the environment?

Absolutely! Additive manufacturing is a great choice for the environment. This is because of the lower waste caused by additive manufacturing processes.