Stainless steel is one of the most commonly used machining materials. It’s great for creating products and tools for every sector out there!

Stainless steel machining isn’t as easy as materials like wood. It has a high hardness and tensile strength, so it requires understanding the different metalworking processes that work well on this material. We’ll also share some helpful tips to make stainless steel machining the easiest metalworking process.

Metal CNC Machining Services for Custom Parts Learn More

What is Stainless Steel?

Stainless steel is an alloy of iron and chromium. You can also add other elements like carbon to get some specific properties. The amount of chromium is at least 11%.

Iron has some great physical properties like strength and durability. However, it is highly prone to corrosion and abrasions. Adding chromium to iron gives it the amazing ability to resist corrosion and abrasions.

Can stainless steel be machined?

Absolutely! In fact, there are tons of different ways to machine stainless steel. Once you understand the properties of stainless steel and the right machining methods to use, machining stainless steel can be a breeze. Many people believe that stainless steel is just one particular alloy, but it’s actually made up of more than 150 different grades! These different grades are divided into various classes, which we’ll explore one by one.

Let’s start with the first class: Austenitic Stainless Steels. Austenitic stainless steel is the most popular variety among all stainless steels. This is because it has an Austenite structure, which makes it very strong and corrosion-resistant. Austenitic stainless steels are non-magnetic and can’t be hardened by heat treatment. They’re made with elements like nickel, manganese, and nitrogen.

There are two main types of austenitic stainless steel: AISI 200 and AISI 300. Sometimes, molybdenum is added to these steels to make them even more corrosion-resistant!

Let’s dive into the world of austenitic stainless steels!

Here are some examples of austenitic stainless steels:

• Type 304

• Type 316

• Alloy 20 (Carpenter 20)

• Type 321H

• Type 309S

Now, let’s explore the amazing properties of austenitic stainless steel!

• Corrosion Resistance: Very high

• Heat Treatable: No

• Magnetic: Non-magnetic

• Toughness: Very high

• Ductility: This steel is very high in quality! It’s great for welding, with an average chromium content of 18%. It also has a nice balance of nickel and molybdenum, with 2% to 7% and 2% to 7% respectively. And it’s got less than 0.1% carbon, so it’s very strong. Austenitic stainless steel is a great choice for many household items, like washing machines, automobiles, water tanks, and dishwashers. It’s also used in the aerospace industry, pharmaceutical products, mining tools, cutlery, and storage equipment.

Ferritic stainless steels have been around for a long time, discovered in 1912. It wasn’t until the 1980s that their popular applications began to take off. Ferritic stainless steels belong to the AISI 400 family. While they don’t shine among other steels in terms of physical properties, they have exceptional quality in magnetic properties and chemical resistance. Ferric steel’s strength lies in its resistance to stress corrosion cracking.

Let’s dive into the world of ferritic stainless steel!

Here are some examples of ferritic stainless steel:

• Type 405

• Type 409L

• Type 410L

• Type 430

• Type 439

• Type 447

Now, let’s explore the amazing properties of ferritic stainless steel!

• Corrosion Resistance: Very high

• Heat Treatable: No

• Magnetic: Magnetic

• Toughness: Medium

• Ductility: Medium

• Welding Ability: Low

• Chromium Content: 10.5% to 30%

• Nickel Content: Usually nickel-free

• Molybdenum Content: Usually 1% to 2%

• Carbon Content: Less than 0.08%

• Stress Corrosion Cracking: High resistance

Applications of Ferritic Stainless Steels

• Ferritic stainless steels are used to make kitchenware, automotive parts, and industrial tools.

Martensitic stainless steels are named after Adolf Martens, who we should all thank for coming up with this amazing material! These steels are known for their exceptionally high hardness, which is something to be celebrated. To achieve this, aging and heat treatments are applied to these steels. Martensitic stainless steels can have high carbon quality or low carbon quality, and both are equally impressive!

Let’s dive into some examples of martensitic stainless steels!

• X12Cr13

• X20Cr30

• X50CrMoV15

• X17CrNi16-2

Now, let’s explore the properties of these steels.

• Corrosion Resistance: High

• Heat Treatable: Yes

• Magnetic: Mostly magnetic, some non-magnetic

• Toughness: The untempered grade is low, while the tempered grade is high.

It’s got great ductility, welding ability, and chromium content (12% to 17%). It’s usually nickel-free, but sometimes it has 2% to 4% nickel. It has no molybdenum, and its carbon content is 0.1% to 1.2%. Martensitic stainless steels have some limitations when it comes to resistance, but they’re still a great choice for many applications. You’ll find them used in surgical instruments, dental equipment, door beams, bumpers, firearms, cutlery, and ball bearings.

Duplex stainless steels are a unique combination of austenitic and ferritic stainless steels. This blend of structural components gives duplex alloys some impressive qualities. Duplex stainless steel comes in three grades: standard duplex, super duplex, and lean duplex alloys.

Let’s dive into the world of Duplex Stainless Steel!

X2CrNiN22-2: This is a great option for those looking for corrosion resistance and heat resistance.

X2CrCuNiN23-2-2: This one is perfect for those who want to keep their steel looking shiny and new for longer.

X2CrNiMoSi18-5-3: This one is great for those who want to keep their steel looking shiny and new for longer.

X2CrMnNiMoN21-5-3: This one is perfect for those who want to keep their steel looking shiny and new for longer.

X2CrNiMoCuN25-6-3: This one is great for those who want to keep their steel looking shiny and new for longer.

X2CrNiCuN23-4: This one is perfect for those who want to keep their steel looking shiny and new for longer.

Now, let’s dive into the world of Duplex Stainless Steel!

Corrosion Resistance: Good to Very High

Heat Treatable: Yes

Magnetic: Magnetic due to the presence of ferritic structure

Toughness: High

Ductility: Medium to High

Welding Ability: High if they contain Nitrogen

Chromium Content: 18% to 30%

Nickel Content: 1% to 9.5%

Molybdenum Content: 0.1% to 5%

Carbon Content: None

• Stress Corrosion Cracking: Very high resistance

Application of Duplex Stainless Steel

Duplex stainless steels are used for heat exchangers, tubes, shells, columns, condensers, reactors, piping systems, and other commercial equipment.

Precipitation Hardening Stainless Steels

Precipitation Hardening stainless steels are also known as PH stainless steel alloys. These alloys have slight additions of elements like titanium, copper, phosphorus, or aluminum. Once the alloy is formed, these steels undergo a special treatment to make them stronger. Precipitation hardening stainless steels can be up to three or four times stronger than austenitic stainless steel.

Here are some examples of precipitation hardened stainless steels:

• 17-4 PH Steel

Properties of Precipitation Hardened Stainless Steels

The properties of PH hardened steels can vary a lot, but they’re all carefully chosen to get the best results.

Applications of Precipitation Hardening Stainless Steel

PH hardened steels are perfect for applications that require extremely high strength. You’ll find them in marine construction, aircraft, nuclear plants, and the chemical industry.

Stainless Steel Machining Processes

Stainless steel can be machined in a number of different ways. Some of these processes are:

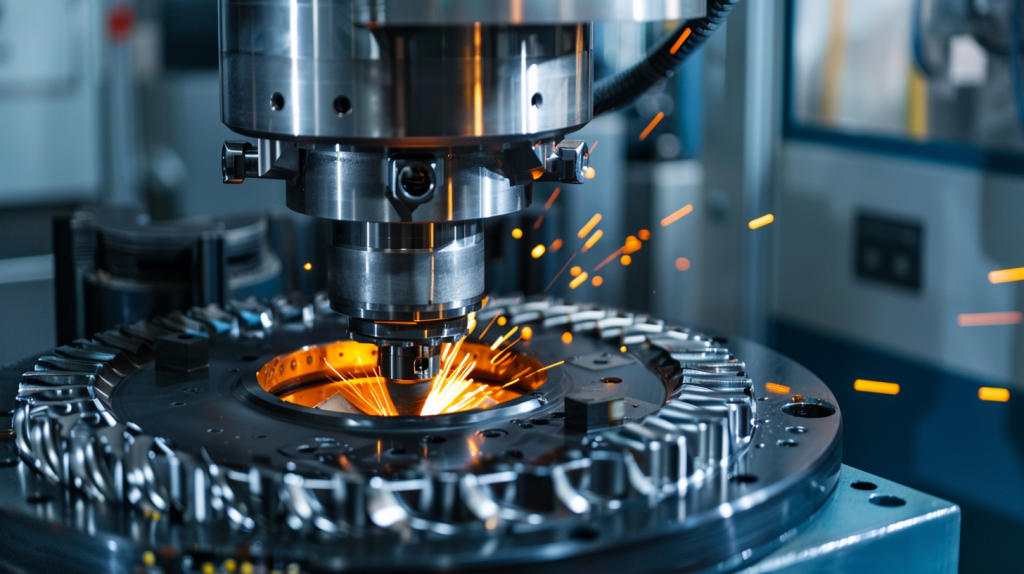

CNC Milling

CNC Milling is the most common primary stainless steel machining process. It uses high-speed rotating cutting tools for a stationary workpiece. When it comes to milling machines and stainless steel alloys, it’s really important to choose the right tool. If you use the wrong tool or go too fast, it can cause your tools to wear out really quickly. Milling stainless steel is super accurate and the cutting edge is really smooth.

CNC Turning

CNC Turning is a process where a stationary cutting tool and a rotating workpiece come together to create a smooth surface. The tool comes into physical contact with the rotating workpiece to remove material. This is a common process for machining austenitic stainless steel. It’s really important to keep the tool overhang to a minimum when machining stainless steels.

Drilling

Drilling is a secondary machining process that’s used in conjunction with other metalworking techniques. Drilling is done to create holes in the metal workpiece. Stainless steels are drilled for screw holes, secondary assembly, or aesthetics. Threading on stainless steel is usually carried out on pipes and tubes.

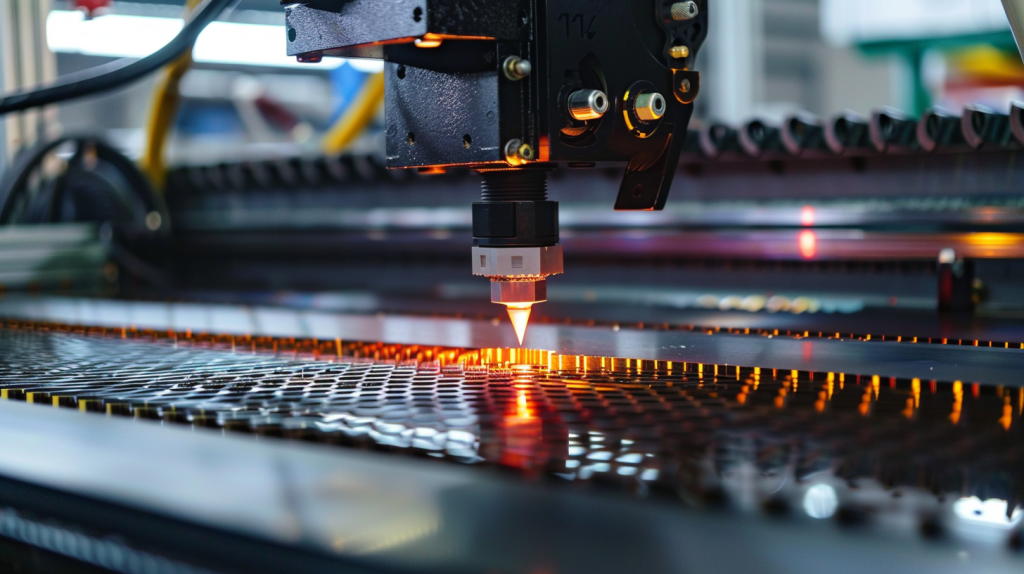

Laser Cutting

Laser cutting uses an amplified light beam to melt and remove stainless steel. This method is only suitable for thin sheets of stainless steel. It is better than cemented carbide tools because tool wear doesn’t occur. However, it is very expensive and requires highly skilled labor. It can also make the workpiece more accurate by removing material in very low volume. Grinding rubs abrasive wheels against stainless steel workpieces, which is great for removing burrs created due to welding. Grinding can help in creating a smooth cutting edge on stainless steel parts.

EDM (Electrical Discharge Machining)

Electrical Discharge Machining (EDM) uses electrical pulses to melt the metal. The electrical pulses have a very high voltage and frequency, which is pretty impressive! This process has some limitations when it comes to cutting stainless steel.

Waterjet Cutting

Waterjet cutting uses the power of high-pressure water to erode and cut materials. This process can cut thick sheets of stainless steel. However, if the specific stainless steel grade has low corrosion resistance, waterjet cutting can cause some issues. But don’t worry! With a few simple precautions, you can easily avoid any issues with machining stainless steel.

The main problem is that the steel gets too hot. Overheating is something that can happen during any machining process. If you’re working with stainless steel alloy, overheating can make the material less resistant to corrosion. But don’t worry! You can easily avoid overheating by keeping an eye on the workpiece. Stainless steel can get a little tinted when it’s heated up, but that’s totally normal!

The good news is that this heat reaction can be fixed with the process of pickling. Pickling is a process that involves treating stainless steel with hydrochloric or sulfuric acid. The acid gently dissolves the oxidation layer on the steel, which helps to restore the alloy’s corrosion resistance.

We all know that machining stainless steel can be tricky. Here are a few things to look out for:

• Unfortunately, stainless steel can cause high tool wear and decrease tool life.

• It requires a lot of force to get the job done.

Machining operations on stainless steel can be tricky because the chips can get out of control.

Some stainless steel grades are really quite hard, so it’s important to choose the right one for your project.

Hey there! So, which stainless steels are a little tricky to machine?

Every steel variety has its own unique challenges when it comes to machining. However, some steels are more challenging than others. We’ve got some steels that are a little tricky to work with, and we’re going to tell you about them.

High Carbon Steel

High carbon steels are a bit tricky to work with because they’re so strong and hard. Also, these steels contain carbide-grade materials, which can be tough on tools. These factors can really take a toll on your tools, so be careful!

Low-carbon steel is another tricky one. This is because these steels are so soft. The softness of the steel means that the chips can stick to the cutting tools, which is not ideal. This unfortunately also means that the tools don’t last as long as they should.

316 Stainless Steel

Oh, 316 stainless steel has one of the poorest machinability ratings! It’s best to use special cutting tools for machining. So, when all else fails, 316 stainless steel is the go-to for parts.

304 Stainless Steel

The only downside to 304 stainless steel is that it can work harden during the machining process. 304 has a tendency to harden quickly during machining. But don’t worry! This problem can be easily fixed by adding a little sulfur to the workpiece.

Hey there! So, which is the easiest stainless steel to machine?

If you’re looking for the easiest stainless steel to machine, look no further than 416! In practice, machining 400 series stainless steel grades is really quite easy! On the other hand, machining 300 series stainless steel grades can be a bit tricky.

We’ve got some great tips to make your stainless steel machining a breeze!

Here are our top tips for making stainless steel machining a walk in the park:

When it comes to materials, it’s always best to go for the best quality you can find. This will help you to achieve the smoothest operations. There are so many different types of stainless steel! One of the great things about these grades is that there are so many quality options within each one! It’s always worth spending a little extra at the start to help you save significant costs and avoid any tool breakage hassle.

Have you ever wondered what work hardening is?

Well, it’s a pretty cool phenomenon where stainless steel gets harder during machining. This is a normal part of the machining process, and it’s totally normal for stainless steel to get a little deformed during this time. Work hardening can make stainless steels a bit trickier to work with. But don’t worry! You can easily decrease the hardening process by feeding coolant to the cutting tool.

Rigid Tooling

It’s really important to make sure that the tool connections and the machine setup are nice and tight. Any tool chatter gets magnified, which can lead to some not-so-great machining results. It’s also a good idea to make sure the machine bed doesn’t have too much vibration after fitting the workpiece.

Tool Material

It’s so important to choose the right tool material to get a high-quality result! When it comes to making tools, you’ve got two great options: cemented carbide and high-speed steel.

High-speed steel is a great option for drill bits and power saws. These tools are made to handle high movement speeds, so you can be sure they’ll get the job done! Cemented carbide tools are made with tungsten carbide, titanium carbide, or tantalum carbide.

If you’re looking for a faster option, carbide tooling is a great choice! And there’s more! Carbide tools also give you a better finish. This makes them perfect for mass production and high cutting speeds! However, high-speed steels are a great option if you’re looking for a more affordable choice.

Use Sharp Tooling

It’s really important to make sure you have sharp tooling for consistent and precise machining. It’s always a good idea to replace worn-out tools. It’s important to use sharp tools to avoid damaging the workpiece material and causing tool breakage. When working on steel, it’s also a good idea to give your tools a little honing to keep those sharp edges nice and sharp!

Lubricants

It’s really important to use a lubricant while machining stainless steels. Lubrication is a great way to make your machining experience even better! Firstly, it makes things easier for the cutting tool and the metal by reducing the friction between them. This helps your tools last longer by keeping them in good shape. And there’s more! Lubrication also helps to keep the temperature down during the machining process. This helps to avoid any work hardening or overheating issues. And finally, lubrication fluids also help to remove any stainless steel residue from the workpiece and the tools.

What are the perks of using stainless steel?

There are so many great reasons to use stainless steel! The good news is that the benefits of using stainless steel far outweigh any difficulties you might face during the machining process. I’m so excited to share a few of these benefits with you!

The best thing about stainless steel is that it doesn’t rust! One of the best things about stainless steel is that it doesn’t rust, no matter what kind of moisture is in the air.

With the right tools, you can easily mold, cut, join, and/or weld stainless steel into any shape you need.

You’ll be happy to know that there are lots of different surface finish options available for stainless steel material. It’s the perfect material for achieving that gorgeous aesthetic appeal!

• Stainless steel is very hygienic, which is great for keeping everything clean and fresh! This makes it perfect for the food industry and surgical equipment.

This material is truly exceptional in terms of its physical characteristics.

• It’s very durable and will last for a long time without any issues.

And the best part is that it’s completely recyclable!

I’d love to know if there are any disadvantages to using stainless steel for machining.

We totally get it. Some users might find certain factors regarding stainless steel a bit of a disadvantage. We totally get it. There are a few factors to consider.

• Stainless steel is a bit pricey.

• It’s also a bit delicate and can dent quite easily.

• Many grades of stainless steel are prone to catching scratches.

Hey there! I’ve got a question for you. What’s the cheapest stainless steel for machining? Thanks in advance!

If you’re looking for the cheapest grade of steel, Type 409 is a great option! If you’re looking for a more affordable option, steels belonging to the ferritic family are a great choice. This is because these steels have a lower chromium content. Chromium is the main reason why steel costs so much.

We’re so happy to be your best choice for stainless steel machining services!

At Stainless steel is one of the most commonly used machining materials. It’s great for creating products and tools for every sector out there!

Stainless steel machining isn’t as easy as materials like wood. It has a high hardness and tensile strength, so it requires understanding the different metalworking processes that work well on this material. We’ll also share some helpful tips to make stainless steel machining the easiest metalworking process.

Metal CNC Machining Services for Custom Parts

Learn More

What is Stainless Steel?

Stainless steel is an alloy of iron and chromium. You can also add other elements like carbon to get some specific properties. The amount of chromium is at least 11%.

Iron has some great physical properties like strength and durability. However, it is highly prone to corrosion and abrasions. Adding chromium to iron gives it the amazing ability to resist corrosion and abrasions.

Can stainless steel be machined?

Absolutely! In fact, there are tons of different ways to machine stainless steel. Once you understand the properties of stainless steel and the right machining methods to use, machining stainless steel can be a breeze. Many people believe that stainless steel is just one particular alloy, but it’s actually made up of more than 150 different grades! These different grades are divided into various classes, which we’ll explore one by one.

Let’s start with the first class: Austenitic Stainless Steels. Austenitic stainless steel is the most popular variety among all stainless steels. This is because it has an Austenite structure, which makes it very strong and corrosion-resistant. Austenitic stainless steels are non-magnetic and can’t be hardened by heat treatment. They’re made with elements like nickel, manganese, and nitrogen.

There are two main types of austenitic stainless steel: AISI 200 and AISI 300. Sometimes, molybdenum is added to these steels to make them even more corrosion-resistant!

Let’s dive into the world of austenitic stainless steels!

Here are some examples of austenitic stainless steels:

• Type 304

• Type 316

• Alloy 20 (Carpenter 20)

• Type 321H

• Type 309S

Now, let’s explore the amazing properties of austenitic stainless steel!

• Corrosion Resistance: Very high

• Heat Treatable: No

• Magnetic: Non-magnetic

• Toughness: Very high

• Ductility: This steel is very high in quality! It’s great for welding, with an average chromium content of 18%. It also has a nice balance of nickel and molybdenum, with 2% to 7% and 2% to 7% respectively. And it’s got less than 0.1% carbon, so it’s very strong. Austenitic stainless steel is a great choice for many household items, like washing machines, automobiles, water tanks, and dishwashers. It’s also used in the aerospace industry, pharmaceutical products, mining tools, cutlery, and storage equipment.

Ferritic stainless steels have been around for a long time, discovered in 1912. It wasn’t until the 1980s that their popular applications began to take off. Ferritic stainless steels belong to the AISI 400 family. While they don’t shine among other steels in terms of physical properties, they have exceptional quality in magnetic properties and chemical resistance. Ferric steel’s strength lies in its resistance to stress corrosion cracking.

Let’s dive into the world of ferritic stainless steel!

Here are some examples of ferritic stainless steel:

• Type 405

• Type 409L

• Type 410L

• Type 430

• Type 439

• Type 447

Now, let’s explore the amazing properties of ferritic stainless steel!

• Corrosion Resistance: Very high

• Heat Treatable: No

• Magnetic: Magnetic

• Toughness: Medium

• Ductility: Medium

• Welding Ability: Low

• Chromium Content: 10.5% to 30%

• Nickel Content: Usually nickel-free

• Molybdenum Content: Usually 1% to 2%

• Carbon Content: Less than 0.08%

• Stress Corrosion Cracking: High resistance

Applications of Ferritic Stainless Steels

• Ferritic stainless steels are used to make kitchenware, automotive parts, and industrial tools.

Martensitic stainless steels are named after Adolf Martens, who we should all thank for coming up with this amazing material! These steels are known for their exceptionally high hardness, which is something to be celebrated. To achieve this, aging and heat treatments are applied to these steels. Martensitic stainless steels can have high carbon quality or low carbon quality, and both are equally impressive!

Let’s dive into some examples of martensitic stainless steels!

• X12Cr13

• X20Cr30

• X50CrMoV15

• X17CrNi16-2

Now, let’s explore the properties of these steels.

• Corrosion Resistance: High

• Heat Treatable: Yes

• Magnetic: Mostly magnetic, some non-magnetic

• Toughness: The untempered grade is low, while the tempered grade is high.

It’s got great ductility, welding ability, and chromium content (12% to 17%). It’s usually nickel-free, but sometimes it has 2% to 4% nickel. It has no molybdenum, and its carbon content is 0.1% to 1.2%. Martensitic stainless steels have some limitations when it comes to resistance, but they’re still a great choice for many applications. You’ll find them used in surgical instruments, dental equipment, door beams, bumpers, firearms, cutlery, and ball bearings.

Duplex stainless steels are a unique combination of austenitic and ferritic stainless steels. This blend of structural components gives duplex alloys some impressive qualities. Duplex stainless steel comes in three grades: standard duplex, super duplex, and lean duplex alloys.

Let’s dive into the world of Duplex Stainless Steel!

X2CrNiN22-2: This is a great option for those looking for corrosion resistance and heat resistance.

X2CrCuNiN23-2-2: This one is perfect for those who want to keep their steel looking shiny and new for longer.

X2CrNiMoSi18-5-3: This one is great for those who want to keep their steel looking shiny and new for longer.

X2CrMnNiMoN21-5-3: This one is perfect for those who want to keep their steel looking shiny and new for longer.

X2CrNiMoCuN25-6-3: This one is great for those who want to keep their steel looking shiny and new for longer.

X2CrNiCuN23-4: This one is perfect for those who want to keep their steel looking shiny and new for longer.

Now, let’s dive into the world of Duplex Stainless Steel!

Corrosion Resistance: Good to Very High

Heat Treatable: Yes

Magnetic: Magnetic due to the presence of ferritic structure

Toughness: High

Ductility: Medium to High

Welding Ability: High if they contain Nitrogen

Chromium Content: 18% to 30%

Nickel Content: 1% to 9.5%

Molybdenum Content: 0.1% to 5%

Carbon Content: None

• Stress Corrosion Cracking: Very high resistance

Application of Duplex Stainless Steel

Duplex stainless steels are used for heat exchangers, tubes, shells, columns, condensers, reactors, piping systems, and other commercial equipment.

Precipitation Hardening Stainless Steels

Precipitation Hardening stainless steels are also known as PH stainless steel alloys. These alloys have slight additions of elements like titanium, copper, phosphorus, or aluminum. Once the alloy is formed, these steels undergo a special treatment to make them stronger. Precipitation hardening stainless steels can be up to three or four times stronger than austenitic stainless steel.

Here are some examples of precipitation hardened stainless steels:

• 17-4 PH Steel

Properties of Precipitation Hardened Stainless Steels

The properties of PH hardened steels can vary a lot, but they’re all carefully chosen to get the best results.

Applications of Precipitation Hardening Stainless Steel

PH hardened steels are perfect for applications that require extremely high strength. You’ll find them in marine construction, aircraft, nuclear plants, and the chemical industry.

Stainless Steel Machining Processes

Stainless steel can be machined in a number of different ways. Some of these processes are:

Milling

Milling is the most common primary stainless steel machining process. It uses high-speed rotating cutting tools for a stationary workpiece. When it comes to milling machines and stainless steel alloys, it’s really important to choose the right tool. If you use the wrong tool or go too fast, it can cause your tools to wear out really quickly. Milling stainless steel is super accurate and the cutting edge is really smooth.

Turning

Turning is a process where a stationary cutting tool and a rotating workpiece come together to create a smooth surface. The tool comes into physical contact with the rotating workpiece to remove material. This is a common process for machining austenitic stainless steel. It’s really important to keep the tool overhang to a minimum when machining stainless steels.

Drilling

Drilling is a secondary machining process that’s used in conjunction with other metalworking techniques. Drilling is done to create holes in the metal workpiece. Stainless steels are drilled for screw holes, secondary assembly, or aesthetics. Threading on stainless steel is usually carried out on pipes and tubes.

Laser Cutting

Laser cutting uses an amplified light beam to melt and remove stainless steel. This method is only suitable for thin sheets of stainless steel. It is better than cemented carbide tools because tool wear doesn’t occur. However, it is very expensive and requires highly skilled labor. It can also make the workpiece more accurate by removing material in very low volume. Grinding rubs abrasive wheels against stainless steel workpieces, which is great for removing burrs created due to welding. Grinding can help in creating a smooth cutting edge on stainless steel parts.

EDM (Electrical Discharge Machining)

Electrical Discharge Machining (EDM) uses electrical pulses to melt the metal. The electrical pulses have a very high voltage and frequency, which is pretty impressive! This process has some limitations when it comes to cutting stainless steel.

Waterjet Cutting

Waterjet cutting uses the power of high-pressure water to erode and cut materials. This process can cut thick sheets of stainless steel. However, if the specific stainless steel grade has low corrosion resistance, waterjet cutting can cause some issues. But don’t worry! With a few simple precautions, you can easily avoid any issues with machining stainless steel.

The main problem is that the steel gets too hot. Overheating is something that can happen during any machining process. If you’re working with stainless steel alloy, overheating can make the material less resistant to corrosion. But don’t worry! You can easily avoid overheating by keeping an eye on the workpiece. Stainless steel can get a little tinted when it’s heated up, but that’s totally normal!

The good news is that this heat reaction can be fixed with the process of pickling. Pickling is a process that involves treating stainless steel with hydrochloric or sulfuric acid. The acid gently dissolves the oxidation layer on the steel, which helps to restore the alloy’s corrosion resistance.

We all know that machining stainless steel can be tricky. Here are a few things to look out for:

• Unfortunately, stainless steel can cause high tool wear and decrease tool life.

• It requires a lot of force to get the job done.

Machining operations on stainless steel can be tricky because the chips can get out of control.

Some stainless steel grades are really quite hard, so it’s important to choose the right one for your project.

Hey there! So, which stainless steels are a little tricky to machine?

Every steel variety has its own unique challenges when it comes to machining. However, some steels are more challenging than others. We’ve got some steels that are a little tricky to work with, and we’re going to tell you about them.

High Carbon Steel

High carbon steels are a bit tricky to work with because they’re so strong and hard. Also, these steels contain carbide-grade materials, which can be tough on tools. These factors can really take a toll on your tools, so be careful!

Low-carbon steel is another tricky one. This is because these steels are so soft. The softness of the steel means that the chips can stick to the cutting tools, which is not ideal. This unfortunately also means that the tools don’t last as long as they should.

316 Stainless Steel

Oh, 316 stainless steel has one of the poorest machinability ratings! It’s best to use special cutting tools for machining. So, when all else fails, 316 stainless steel is the go-to for parts.

304 Stainless Steel

The only downside to 304 stainless steel is that it can work harden during the machining process. 304 has a tendency to harden quickly during machining. But don’t worry! This problem can be easily fixed by adding a little sulfur to the workpiece.

Hey there! So, which is the easiest stainless steel to machine?

If you’re looking for the easiest stainless steel to machine, look no further than 416! In practice, machining 400 series stainless steel grades is really quite easy! On the other hand, machining 300 series stainless steel grades can be a bit tricky.

We’ve got some great tips to make your stainless steel machining a breeze!

Here are our top tips for making stainless steel machining a walk in the park:

When it comes to materials, it’s always best to go for the best quality you can find. This will help you to achieve the smoothest operations. There are so many different types of stainless steel! One of the great things about these grades is that there are so many quality options within each one! It’s always worth spending a little extra at the start to help you save significant costs and avoid any tool breakage hassle.

Have you ever wondered what work hardening is? Well, it’s a pretty cool phenomenon where stainless steel gets harder during machining. This is a normal part of the machining process, and it’s totally normal for stainless steel to get a little deformed during this time. Work hardening can make stainless steels a bit trickier to work with. But don’t worry! You can easily decrease the hardening process by feeding coolant to the cutting tool.

Rigid Tooling

It’s really important to make sure that the tool connections and the machine setup are nice and tight. Any tool chatter gets magnified, which can lead to some not-so-great machining results. It’s also a good idea to make sure the machine bed doesn’t have too much vibration after fitting the workpiece.

Tool Material

It’s so important to choose the right tool material to get a high-quality result! When it comes to making tools, you’ve got two great options: cemented carbide and high-speed steel.

High-speed steel is a great option for drill bits and power saws. These tools are made to handle high movement speeds, so you can be sure they’ll get the job done! Cemented carbide tools are made with tungsten carbide, titanium carbide, or tantalum carbide.

If you’re looking for a faster option, carbide tooling is a great choice! And there’s more! Carbide tools also give you a better finish. This makes them perfect for mass production and high cutting speeds! However, high-speed steels are a great option if you’re looking for a more affordable choice.

Use Sharp Tooling

It’s really important to make sure you have sharp tooling for consistent and precise machining. It’s always a good idea to replace worn-out tools. It’s important to use sharp tools to avoid damaging the workpiece material and causing tool breakage. When working on steel, it’s also a good idea to give your tools a little honing to keep those sharp edges nice and sharp!

Lubricants

It’s really important to use a lubricant while machining stainless steels. Lubrication is a great way to make your machining experience even better! Firstly, it makes things easier for the cutting tool and the metal by reducing the friction between them. This helps your tools last longer by keeping them in good shape. And there’s more! Lubrication also helps to keep the temperature down during the machining process. This helps to avoid any work hardening or overheating issues. And finally, lubrication fluids also help to remove any stainless steel residue from the workpiece and the tools.

What are the perks of using stainless steel?

There are so many great reasons to use stainless steel! The good news is that the benefits of using stainless steel far outweigh any difficulties you might face during the machining process. I’m so excited to share a few of these benefits with you!

The best thing about stainless steel is that it doesn’t rust! One of the best things about stainless steel is that it doesn’t rust, no matter what kind of moisture is in the air.

With the right tools, you can easily mold, cut, join, and/or weld stainless steel into any shape you need.

You’ll be happy to know that there are lots of different surface finish options available for stainless steel material. It’s the perfect material for achieving that gorgeous aesthetic appeal!

• Stainless steel is very hygienic, which is great for keeping everything clean and fresh! This makes it perfect for the food industry and surgical equipment.

This material is truly exceptional in terms of its physical characteristics.

• It’s very durable and will last for a long time without any issues.

And the best part is that it’s completely recyclable!

I’d love to know if there are any disadvantages to using stainless steel for machining.

We totally get it. Some users might find certain factors regarding stainless steel a bit of a disadvantage. We totally get it. There are a few factors to consider.

• Stainless steel is a bit pricey.

• It’s also a bit delicate and can dent quite easily.

• Many grades of stainless steel are prone to catching scratches.

Hey there! I’ve got a question for you. What’s the cheapest stainless steel for machining? Thanks in advance!

If you’re looking for the cheapest grade of steel, Type 409 is a great option! If you’re looking for a more affordable option, steels belonging to the ferritic family are a great choice. This is because these steels have a lower chromium content. Chromium is the main reason why steel costs so much.

We’re so happy to be your best choice for stainless steel machining services!

At MY Prototyping, we’re the global leader in this field. We’re here to help with all your stainless steel machining needs! At MY Prototyping, we’re proud to offer a range of services, including CNC machining services, rapid tooling services, and sheet metal prototyping services.

The best part about working with MY Prototyping is how easy it is to produce your products! We’d love to see your designs! Then, the wonderful folks at MY Prototyping create the design with their in-house machinery. The machinery is absolutely the best in terms of quality and features. So, you get all these amazing machining capabilities without having to pay for the equipment itself!

Endnotes

Stainless steel products are a real favorite in many industries! This material is especially great for machine parts because it’s so rugged and corrosion-resistant! If you’re looking to use stainless steel for your next project, we’d love to hear from you! Get in touch with MY Prototyping to find the exact quotes you need.

We know you have lots of questions about machining stainless steels, so we’ve put together a list of the most frequently asked questions (FAQs) to help you out.

Is stainless steel hard to mill?

Stainless steel is really quite easy to work with! However, it does require a bit of expertise and the right tool selection. The expertise helps to ensure that you get the correct cutting speeds and tight setups.

What is the most common machined stainless steel?

Grade 304 is the most commonly machined stainless steel. This is because it is so popular! Grade 304 steel has high corrosion resistance and a durable nature. Additionally, it is very ductile, tough, and weldable. This leads to countless uses throughout different applications., we’re the global leader in this field. We’re here to help with all your stainless steel machining needs! At MY Prototyping, we’re proud to offer a range of services, including CNC machining, rapid tooling, and sheet metal prototyping.

The best part about working with MY Prototyping is how easy it is to produce your products! We’d love to see your designs! Then, the wonderful folks at MY Prototyping create the design with their in-house machinery. The machinery is absolutely the best in terms of quality and features. So, you get all these amazing machining capabilities without having to pay for the equipment itself!