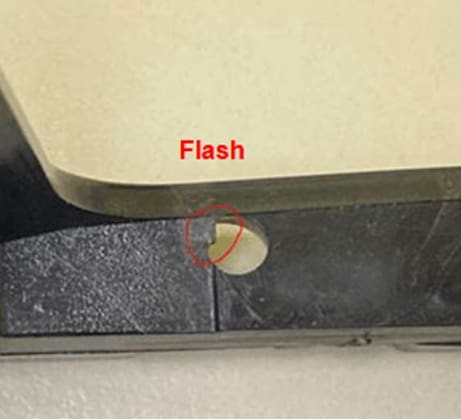

If plastic pressure in the mold is greater than the clamp force,injection molding flash will occur

The prevention of injection molding flash is a significant challenge in the field of plastic part manufacturing. Flash, or flashing, is a common phenomenon associated with injection molding, which is the most widely used manufacturing process for plastic parts. Flash occurs when a line of excess material builds up on the outside of a molded part, typically after leaking through the parting line of the mold. While a small amount of flash is normal, excessive flash can affect the cosmetic appearance, surface texture, and assembly of parts.

This article examines the principal strategies for preventing injection molding flash, as well as methods for removing flash (deflashing) after the molding process is complete.

What is injection molding flash?

Flash is excess plastic that forms on the surface of parts produced by plastic injection molding (or similar processes such as casting). In the majority of cases, flash occurs when material escapes between two mold halves at the parting line. Molded parts will almost always display witness marks, which are signs of tooling features like core pins. Therefore, product designers should design parts so that these marks are as inconspicuous as possible. One type of witness mark is the witness line, which is a line on the molded part that shows the parting line of the mold halves.

Flash can be considered a more severe case of a witness line. Unlike a witness line, flash is not only visible on the surface; it also physically protrudes from it. This can give rise to a number of issues. The flash may be sharp, making the part dangerous to handle. Alternatively, it may prevent the part from mating with other components due to its reduced dimensional accuracy.

There are a number of causes of injection mold flash, including:

Poor alignment between mold halves, worn, damaged, or dirty molds, poor venting, unbalanced plastic flow, insufficient clamping force, and low plastic viscosity are among the causes of flash. In general, up to 0.1 mm of flash is considered acceptable unless the part has unique needs in terms of surface flatness. It is possible to reduce flash below this amount, but the cost of tooling may increase.

Preventing flash

The prevention or minimization of flash can involve steps at both the moldmaking and molding stages. Improved molds are less likely to produce flash, but proper handling of the molding process is also essential to minimize flash and other injection molding defects. In the event that the mold halves are not properly aligned and do not fit snugly together, they are unable to close properly, allowing material to escape. This escaped material then solidifies as flash on the outside of the moldings.

During the toolmaking stage, the process of mold fitting is carried out to ensure that the mold halves fit together properly without gaps that can cause flash. If the mold halves are not properly aligned, it becomes very difficult to eliminate flash.

Toolmakers are also responsible for the venting of a mold. Vents in the tooling allow air to escape, which enables the molten plastic to fill the mold cavity entirely. Proper venting can also minimize flash. How? Poorly vented molds require higher injection pressures, which can end up forcing the two mold halves apart, creating a gap between them which leads to flash.

Another tooling consideration is flow paths. If some flow paths to the mold cavity are longer than others, unbalanced filling can occur, leading to discrepancies and air traps throughout the mold cavity. Unbalanced flow can also cause flash. Flow leaders and deflectors can be used to ensure balance during filling.

It should be noted that molds are not indestructible, and wear over time can worsen mold alignment and create gaps that lead to flash. It is advisable to carry out maintenance and refitting of the mold if the two halves do not fit snugly together. In addition, regular cleaning should be performed to prevent the buildup or dirt and debris that can prevent effective clamping.

The parting line placement of the mold is another important consideration during the initial moldmaking stage. Although this does not prevent flash, it can ensure that flash occurs in a location that minimizes its aesthetic and functional impact on the part.

Molding process improvements

A well-fitted mold is less likely to produce flash, but the molding process itself also contains several variables that can affect the extent of flash on molded parts. One of the most common causes of excessive flashing is insufficient clamping force. Clamping forces—typically applied via hydraulic or mechanical clamping systems—are required to keep a mold closed during injection, and they must counter the pressure of the injection itself. In the event that the clamping force is insufficient, the mold may open slightly, allowing material to escape and flash to form. High-viscosity materials and thin-walled parts require greater clamping forces. Uneven clamping and molding forces can lead to other issues such as mold deflection, which can also lead to increased flash. The nature of the molding material can also affect flash. Low-viscosity molten plastic is more likely to escape from the mold and cause flash because it flows more freely and can therefore seep through gaps in the parting line. Although some plastics have inherently low viscosity, the viscosity can be increased by using a lower melt temperature in the molding machine.

Removing flash

Injection molding flash cannot always be prevented prior to molding. Fortunately, it is possible to remove flash from molded parts using post-processing techniques. The process of removing injection molding flash from finished moldings is referred to as deflashing. This procedure is more straightforward for soft materials, such as silicone rubber, but can also be applied to hard plastics. One deflashing method involves the use of manual tools, such as knives or files. This approach offers the advantage of precision, as the human operator is responsible for identifying the flash and non-flash material. This approach is also suitable for brittle parts that could be damaged by machine-based deflashing methods. However, this process is expensive at scale, as it must be repeated for each individual molding.

Another deflashing option is the use of a tool and die system. In this approach, the molding is placed within a die shaped like the final part and punched through the opening to quickly remove flash. This option is typically faster than manual trimming for very large batches, though it requires extra machinery and is still slower than batch deflashing processes. If manual or die punch flash removal is not possible, batch deflashing processes can be employed. These processes are much faster than manual deflashing, but there is a risk that pieces of the component will be broken off accidentally. One batch deflashing technique involves using blast media, which can remove excess material like flash from the finished moldings. A related method is tumbling, in which the moldings are placed in a vibrating chamber along with non-abrasive media such as ceramic beads. These techniques can rapidly remove flash from multiple parts, but may not be suitable for delicate or brittle components. Blasting and tumbling can both be assisted by cryogenic freezing of the moldings. The use of cryogenic freezing techniques, such as the application of liquid nitrogen, can render the flash material extremely brittle, thereby facilitating its removal via blasting or tumbling. The application of cryogenic deflashing and deburring techniques can assist in maintaining critical tolerances and ensuring consistency between parts.

Molding with MY Prototyping

MY Prototyping is a prototyping and small-batch production specialist with extensive experience in the production of injection molded parts. We provide a comprehensive range of injection molding services, offering several finishing options to ensure the production of high-quality parts with minimal flash.

To request a free quote, please contact us today.