- As we stand at the intersection of technology and creativity, a paradigm shift is palpably reshaping the way we design and create. At the heart of this revolution is a powerful tool that has radically changed the face of multiple industries: Computer Aided Design (CAD).But what exactly is this much-discussed tool, and why all the fuss? This comprehensive guide will take you through everything you need to know about CAD, from its origins and benefits to its impact in various fields.

What is Computer Aided Design?

Computer-aided design (CAD) refers to the use of computer systems to assist in the creation, modification, analysis, or optimization of a design. Simply put, CAD is a type of software that allows engineers and designers to create products, engineering drawings, and models on a computer rather than on a drawing board.

Modern CAD packages also often allow a user to approach design in a different way, creating three-dimensional solid volumes or surface models instead of two-dimensional projected views. As a result, computer-aided design has become an important technology used by engineers, architects, and even fashion designers in their design processes.

A brief history of computer-aided design

The history of computer-aided design dates back to the 1960s, when engineers began using it as a drafting tool. At that time, CAD systems were high-speed, stand-alone mainframe computers that were not user-friendly and were used for very specific applications.

However, as computers and technology evolved, computer-aided design evolved from a basic drafting system to a more robust and intuitive design tool. Today, it’s used for a wide range of applications, from conceptual design and product layout to defining manufacturing methods for components.

What are the different types of computer-aided design?

The world of CAD is vast and offers a wide range of tools to meet different design needs. Below are some of the more common types:

2D CAD

Two-dimensional, or 2D CAD, involves the creation of flat, two-dimensional drawings composed of lines, circles, and curves. 2D computer-aided design is typically used for architectural blueprints or engineering layouts.

3D CAD

Three-dimensional CAD, or 3D CAD, is more advanced and involves the creation of solid objects in three-dimensional space. 3D CAD allows engineers and architects to view and manipulate their designs from different angles, giving them a better understanding of how the final product will look and function.

Freeform CAD

Freeform CAD tools enable the design of complex and unconventional shapes that may not be possible with traditional 2D or 3D CAD tools. This type of computer-aided design is often used in the fashion and entertainment industries for tasks such as designing clothing or creating CGI characters.

Where is computer-aided design used and in what industries?

CAD is used in a wide range of industries, from architecture and engineering to fashion design and entertainment. This technology has become a cornerstone for many companies, allowing them to streamline their design processes and produce more detailed and accurate designs.

Engineering projects

Engineering projects rely heavily on CAD software. Engineers use CAD to create designs and engineering drawings of machines, systems, and infrastructure. For example, CAD is used to design automotive parts, bridges, tunnels, and even in aerospace engineering to design aircraft and spacecraft.

It allows engineers to manipulate designs in three dimensions (3D), analyze them from any angle, and identify interferences or errors. It also enables the creation of two-dimensional projected views, or “drawings,” from the 3D models for the final engineering drawing views.

Architecture and Interior Design

CAD plays a central role in both architecture and interior design. Architects use it to create detailed architectural designs, from conceptual design to layout to final design. The designs are not limited to the exterior of the building, but also include intricate interior design details.

Interior designers use CAD to optimize space, experiment with different layouts, and visualize the final look in 3D before physical construction begins. The CAD model becomes a valuable communication tool between architects, interior designers, and clients.

Manufacturing and product design

Computer-aided design is having a significant impact on the manufacturing industry, radically changing traditional manufacturing methods. It enables the creation of accurate 3D models of product designs that serve as digital prototypes before actual manufacturing begins. The precision of CAD helps identify potential design flaws, thereby reducing product development costs. CAD also facilitates rapid prototyping, reducing the need for costly physical prototypes.

In the realm of product design, CAD is essential for a wide variety of objects. From the creation of complex electronic devices to simple pieces of furniture, CAD makes it all seamless. Even industries such as jewelry and fashion have embraced CAD to create intricate designs.

CNC Machining

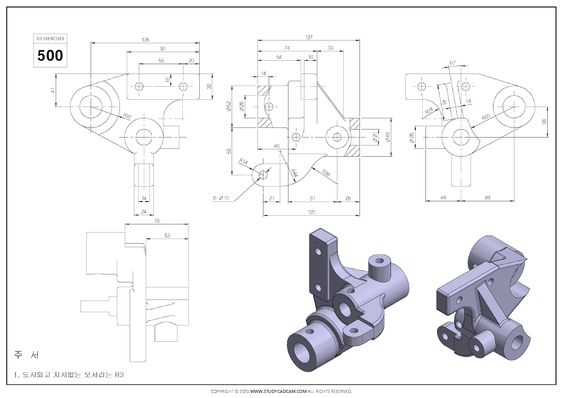

In the world of machining, CAD becomes an essential tool that dramatically increases efficiency and precision. This industry focuses on creating parts by removing material from a workpiece using processes such as drilling, milling, turning, and grinding. These tasks, which can be complex and time-consuming when performed manually, are greatly simplified through the use of CAD.

Machinists use CAD software to develop intricate designs and engineering drawings of the parts to be produced. The CAD system helps visualize these parts in three dimensions, facilitating a thorough understanding of their geometry and features before the machining process begins. This visualization is critical for planning the manufacturing process, determining cutting paths, and selecting appropriate tools and fixtures.

In addition, computer-aided design supports the creation of accurate digital prototypes that mimic real-world objects, including the finest details of their shape and geometry. By simulating the cutting process, machinists can identify potential problems, optimize designs and eliminate costly mistakes.

In a broader context, CAD is an integral part of Computer Aided Manufacturing (CAM). CAD designs can be seamlessly integrated into CAM systems. These systems then generate G-code, a language that tells computer numerical control (CNC) machines how to cut the real-world objects.

In essence, computer-aided design acts as a blueprint for CNC machining, paving the way for high-speed, high-precision manufacturing with lower production costs and less waste. This advanced application of CAD solidifies its position as an essential tool in modern manufacturing.

Education and Training

Many educational institutions offer CAD certificate programs that provide students with the skills necessary to work effectively with CAD systems. Students pursuing associate or bachelor’s degrees in engineering, architecture, and related fields often find CAD training to be an essential part of their curriculum.

Automotive Industry

In the automotive industry, CAD is used to design every component of a vehicle, from the body to the engine parts. This allows manufacturers to test and modify designs before creating a physical prototype, saving time and money.

Fashion industry

The fashion industry also takes advantage of CAD by creating digital prototypes of clothing designs. These virtual models can be modified and tested for different materials and cuts before any physical components are produced.

What are the advantages of CAD over traditional sketching and hand drawing?

The advent of CAD has redefined traditional sketching and manual drafting, bringing with it a host of benefits. Here are just a few:

Accuracy and precision: CAD tools offer a level of detail and precision that is difficult to achieve with manual drafting. They allow users to zoom in and modify the design down to the smallest detail, resulting in a higher quality final design.

Efficiency and productivity: With CAD, design changes and updates can be made quickly without having to start from scratch as with manual drafting. This increases productivity by saving time and resources.

3D visualization: Unlike manual drafting, CAD provides the ability to create and manipulate 3D models. These 3D models provide a better understanding of the design, including a realistic visualization of the final product.

Error reduction: CAD software includes features that automatically check for inconsistencies, design flaws, or errors in the model, significantly reducing the chance of errors.

Easy sharing and collaboration: CAD files can be easily shared and accessed across platforms, making it easier for teams to work together. Digital files also simplify the process of maintaining, tracking, and updating design documents.

What are the most popular CAD software and tools?

As the demand for CAD has grown, so has the availability of software packages. Here are some of the most popular CAD software and tools:

AutoCAD: Developed by Autodesk, AutoCAD is one of the most widely used CAD tools, offering powerful features for 2D and 3D design and drafting.

SolidWorks: Known for its user-friendly interface and robust features, SolidWorks is primarily used for mechanical design, but also supports other types of design.

CATIA: Developed by Dassault Systems, CATIA is known for its advanced surface modeling capabilities and is widely used in the automotive and aerospace industries.

Revit: Also developed by Autodesk, Revit is specifically designed for building information modeling (BIM), allowing architects and engineers to design and manage building projects.

SketchUp: An intuitive tool popular with architects and interior designers, SketchUp is known for its ease of use in creating 3D models.

Are there any drawbacks to using CAD?

While CAD has many benefits, it’s not without its drawbacks. One of the most commonly cited disadvantages is cost. High-end CAD software can be expensive to purchase and maintain. The hardware required to run these programs efficiently can also be a significant investment.

Learning CAD can also be challenging. While some basic CAD software is easy to use, more advanced systems can have steep learning curves. Professionals may require extensive training to master these tools.

In addition, over-reliance on CAD can stifle creativity. As designs are constrained by the capabilities of the software, designers may find their creativity limited by the tool rather than enhanced by it.

What skills are required for CAD?

Mastering CAD requires both technical skills and a strong understanding of the field in which it’s used. Here are some key skills:

Is CAD difficult to learn?

The complexity of learning CAD depends largely on the software and the individual’s background. Basic CAD software can be learned in a few weeks of dedicated study and practice. However, more advanced software, especially for specific industries such as mechanical engineering or architecture, may require months of training.

Are there CAD certifications?

Yes, many educational institutions and software companies offer CAD certificate programs. These programs typically cover basic concepts, software tools, and real-world applications of CAD. Certifications can demonstrate a level of competency and professionalism in computer-aided design and are often preferred by employers.

The top 5 CAD certifications, based on popularity and industry recognition, are

Autodesk Certified Professional (ACP): This certification is highly regarded and covers a wide range of Autodesk software, including AutoCAD, Revit, and Inventor. Autodesk is a leading provider of CAD software, making this certification highly valuable in the industry.

SolidWorks Certification: SolidWorks is widely used in a variety of industries, and its certification programs, such as Certified SolidWorks Professional (CSWP) and Certified SolidWorks Associate (CSWA), are highly regarded. These certifications validate skills in 3D modeling, assembly design, and drawing production using SolidWorks software.

Siemens PLM Software Certification: Siemens offers certifications for its CAD software solutions, including NX and Solid Edge. Siemens product lifecycle management (PLM) software is widely used in industries such as automotive and aerospace. These certifications demonstrate proficiency in using Siemens PLM software for design and engineering tasks.

CATIA Professional Certification: Developed by Dassault Systèmes, CATIA is widely used in industries such as aerospace, automotive, and manufacturing. The CATIA Professional certification is highly valued and validates expertise in using CATIA for design and engineering purposes.

Certified PTC Creo User: PTC Creo is a powerful CAD software for product design and development. The Certified PTC Creo User certification validates expertise in using Creo for tasks such as part modeling, assembly design, and drawing creation.

What are the differences between CAD and CAM?

CAD and CAM are two technologies that are often used together in the design and manufacturing industries. While both play a critical role in these industries, they serve different purposes.

CAD, or Computer-Aided Design, as we’ve explored, involves the use of computer software to create, modify, analyze, or optimize a design. It is used primarily in the design phase of a product’s lifecycle, transforming conceptual designs into detailed engineering drawings and 3D models. It ensures that designs are accurate, changeable, and ready for manufacturing or construction.

On the other hand, CAM, which stands for Computer-Aided Manufacturing, is the use of software and computer-controlled machines to automate manufacturing processes. It is typically used after the design phase. CAM software takes design data from CAD software and uses it to control the machines that make the final product. It facilitates the manufacturing process by providing detailed instructions to CNC machines on how to make the product.

In summary, while CAD is about designing the product, CAM is about making the product.

What are the future trends in CAD?

As we look to the future, CAD is poised for exciting developments. Here are some trends that we expect to shape the CAD landscape:

Cloud-based CAD: Like many other software applications, computer-aided design is moving to the cloud. Cloud-based CAD enables better collaboration, easier access to designs from anywhere, and lower costs by eliminating the need for expensive hardware and constant software upgrades.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML will play a significant role in CAD. These technologies can automate routine design tasks, identify design patterns, and even suggest design improvements, making the design process more efficient and intelligent.

Virtual Reality (VR) and Augmented Reality (AR): VR and AR can provide immersive design experiences, allowing designers to visualize and interact with 3D models in a more realistic environment. They can also be used to present designs to clients in a more engaging and understandable way.

Generative design: This is a design method in which the designer enters goals and constraints into the CAD software, and the software uses algorithms to generate optimal design options. It allows designers to quickly explore a wide range of design possibilities and can lead to innovative solutions that a human designer might not consider.

Conclusion

Computer-aided design is a critical technology used in a variety of industries, including engineering, architecture, and fashion design. It allows designers to create accurate and detailed engineering drawings, simulate designs, and create digital prototypes. While learning and mastering CAD software can be challenging, the benefits it offers in terms of accuracy, efficiency, and design quality make it a valuable skill for any design professional.

From its humble beginnings as a tool to simplify drafting, computer-aided design has evolved into a complex, intelligent system that is an integral part of modern design and manufacturing processes. As technology continues to advance, the capabilities of CAD will continue to grow, enhancing the design process and helping to create better, more innovative products. Whether you’re a budding designer, an experienced engineer, or simply someone interested in the intersection of design and technology, understanding CAD is sure to be a valuable asset in today’s digital age.

Disclaimer of Warranty

The contents of this website are for informational purposes only. MY Prototyping makes no representations or warranties of any kind, express or implied, as to the accuracy, completeness or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be supplied by third party suppliers or manufacturers through MY Prototyping’s network. Buyers seeking instant quotes for parts are responsible for defining the specific requirements for those parts. Please see our Terms and Conditions for more information.