Milling is one of the most popular machining processes. Milling machines can be found in almost every machining shop. The benefits and capabilities of these machines are far reaching.

People new to the industry often ask what milling is, how it works, and what the different types are. This article will discuss milling technology in detail. It will provide a lot of useful information for beginners and professionals alike. In addition, it contains many tips for improving the quality of milling operations.

What is milling?

Milling is a type of machining that uses a rotating cutter to remove material from a workpiece in a controlled manner. This subtractive manufacturing technique is designed to shape the workpiece into the desired form.

A modern milling machine is often paired with computer numerical control (CNC) to automate the entire process.

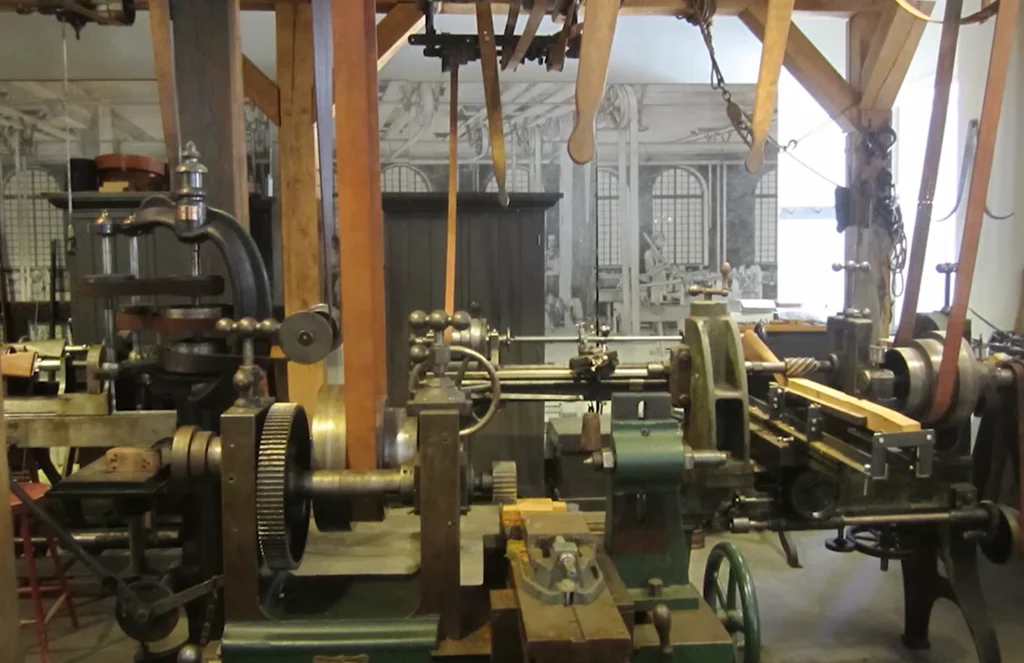

History of milling

Traditionally, complex shapes were created by hand filing. Hand filing created the need for a highly skilled worker.

In the early 19th century, milling machines began to replace these processes. A milling machine eliminated the need for hand filing skills. Instead, operators could use these machines with little experience. Only brief training on the machine was required.

The first milling machines were used to make rifle parts for the army. Milling machines were manually operated until the middle of the 20th century.

With the advent of computer technology, milling machines were integrated with CNC technology in the 1950s. This gave birth to the modern automated milling machines used throughout industry today.

Who invented the milling machine?

Eli Whitney invented the first milling machine in 1818. The purpose of this milling machine was to make rifles for the U.S. government. The basic design and features of this machine were so perfect that it was used for over 150 years. Eli Whitney is also credited with inventing the first cotton gin.

How does milling work?

The main working part of a milling machine is the rotating cutter. This cutting tool is responsible for the material removal process. Milling machines can use both single-point and multi-point cutting tools.

In milling, the cutting tool moves perpendicular to the axis of rotation. For example, when the cutter rotates in the X-Y plane around the Z axis, the cutter also moves in the X-Y plane. The workpiece meets the cutter at the tangent of rotation, resulting in material removal.

What are the different stages of the milling process?

Here is a step-by-step breakdown of the milling process:

Workpiece loading: Preliminary setup involves holding and securing the workpiece on the machine table feed. Wobbly fixtures result in machining errors and poor accuracy.

Tool selection: There are many different types of milling machine tools. Select the right tool for the job based on the workpiece materials and the desired result.

Machine Setup: Machine setup involves adjusting parameters such as spindle speed, coolant flow, feed rate, cutting depth, etc.

Milling Execution: Once setup is complete, the operator starts the actual milling operation.

Roughing: Roughing is the process of removing excess material from the workpiece. This is done to bring the workpiece to a rough approximation of the desired shape. This is done at a high cutting speed and feed rate.

Semi-finishing: Once roughing is complete, the speed of the mill is reduced. The shape of the part is similar to the final part.

Finishing: Finishing is done at a very slow feed rate and low depth of cut. The goal is to improve the dimensional accuracy of the part and make it as close to the machine as possible.

Unload: The operator removes the finished part from the machine.

Inspection and quality control: The finished part is inspected to ensure that there are no defects. If there are any defects or further machining is required, the operator loads the part back into the machine for another finishing pass. This step is repeated until the part meets the required standards.

Post-processing: After milling, the part can undergo any post-processing requirements. Common post-processing operations include deburring, cleaning, grinding, surface finishing, etc.

Types of Milling Operations

There are many types of milling operations. Each of these types can create different parts of shapes. These different types are

End Milling: An end mill is similar in shape to a drill. However, end mills can cut radially and axially. The drill can only cut in the axial direction. A conventional milling machine can only cut in the radial direction.

Face milling: A face mill is used when working on the surface finish of a workpiece. Face milling can turn an uneven surface into a flat surface. It can also create very smooth surfaces. There are several automatic and manual options for face milling.

Chamfer Milling: Chamfer milling is used to create chamfers and bevels. A chamfer mill is also known as a chamfer cutter. Chamfer mills also have other applications such as deburring, countersinking and spotting.

Slot Milling: Slot milling uses a long, rotating cutting tool to create grooves in a workpiece. It is also known as grooving. The slots produced by this operation are deeper than what can be produced by end mills. The slots can be closed or open, with many options for shape.

Peripheral Milling: Peripheral milling places the cutting tool parallel to the workpiece. Therefore, the sides of the cutting tool grind against the work surface instead of the tool tip. This is the opposite of face milling. Peripheral milling is preferred when a large amount of material is to be removed.

Climb milling: In climb milling, the cutting tool rotates in the direction of the feed. This is the opposite of conventional milling, where the cutting tool rotates against the feed direction. The cutting tool climbs over the workpiece, causing a buildup of chips behind it. This eliminates the problem of chips jamming the cutting tool.

Profile Milling: Profile milling is used when machining vertical or vertically inclined surfaces. It can be used in both roughing and finishing operations. Different types of cutting tools in profile milling are based on roughing or finishing operations.

Helical Milling: Helical milling creates helical paths, channels and holes in a cylindrical workpiece. The workpiece rests on rotary tables. The rotating cutter moves along the workpiece at a helical angle. Helical milling is a common type of process for making lubrication holes and paths on a workpiece.

Plunge milling: In plunge milling, the feed rate is in the same direction as the tool axis. This process is also known as Z-axis milling. Plunge milling is often used for roughing. The cutter plunges into the workpiece, cutting pockets in the material.

Thread milling: Thread milling is used to create threads inside a workpiece. Thread mills work only on pre-drilled holes. The thread mill rotates as well as revolves around the internal surface. Thread turning is more commonly used than thread milling.

CNC Milling: CNC stands for Computer Numerical Control. CNC milling uses computer programs to control the motion of the cutting tool. It can produce highly complex parts at high speeds. Depending on the complex shapes required, there are multiple axis options for CNC milling machines.

What is the most common type of milling operation?

End milling and face milling are the most common types of milling operations. They are used in conjunction with most other machining processes. These milling processes can machine the surface and interior of the part.

What equipment is used for milling?

Milling requires a specific set of equipment and a thorough knowledge of how it works. Here are the various tools used in the milling process:

Milling Machine

The milling machine houses the mechanism for moving the tool and the workpiece. The size of the machine depends on the dimensions of the part to be milled. A milling machine contains several components such as the work table, monitor, knee, column, base, saddle, quill, spindle, and more. The specific parts in a milling machine depend largely on the type of milling machine being used.

Milling Cutter

The cutter is the tool used in a router to remove material from the workpiece. Cutters always have the ability to rotate due to the nature of the milling operation. The specific design of the cutter is highly variable depending on the milling process. Some of the common types of milling cutters are

Horizontal milling

End Mill: The end mill is a long and narrow cutting tool with a sharp end. The cutting teeth are on the side and at the end. The bottom of the end mill can be flat, rounded or radiused.

Face Mill: Face mills have multiple cutting points on the side of the cutter. Therefore, face mills cut the workpiece horizontally. The cutting points are made with removable carbide inserts. The inserts can be screwed onto the face mill. This results in a highly efficient milling operation.

Slab Mill: The slab mill cutter is used to machine planes. It is also known as a plane mill. There are multiple cutting teeth on the periphery of the cutter. The teeth can be straight or spiral.

Shell Mill: A shell mill is a modified design of a face mill. It contains a bracket that can accept a mandrel for mounting additional inserts. Sometimes the shell mill is used interchangeably with the face mill.

T-slot cutter: A T-slot cutter is used to machine undercuts. It can widen the bottom of an existing groove in a part. This results in a “T” shaped groove. It is used to make machine tools and keyways.

Fly Cutter: A fly cutter is a single-point cutting tool. It is used to machine a flat surface over a large area. It is similar to a lathe cutter. The cutting edge is usually a replaceable carbide insert.

Ball Nose Cutter: A ball nose cutter is commonly used to machine dies and molds. It is similar to an end mill with a hemispherical rounded end. A ball nose cutter is also referred to as a ball mill or full radius end mill.

Double Angle Mill: The double angle mill is a very versatile cutting tool. It can create threads, chamfers, back chamfers, countersinks, chamfers, grooves and slots in a workpiece. It can also assist in surface finishing operations such as deburring.

Staggered Tooth Mill: The staggered tooth cutter is used to produce deep slots. The staggered tooth design is designed to remove chips from the work surface. This prevents the chips from interfering with the cutting tool operations. It results in longer tool life and cleaner cutting operations.

Form milling: A form mill creates contours on a work surface. The contours can be any shape, such as concave, convex, straight line and irregular shapes. It can also create rounded corners.

Slot Mill: A slot milling cutter is also known as a slot drill. It has a flat end and two flutes. The periphery of the flutes cuts slots in the workpiece. There are many different sizes and pitches of slot cutters available. The ideal size depends on the dimensions of the slot.

Woodruff Mill: The Woodruff cutter makes slots in horizontal milling machines. It has a flat end and multiple cutting teeth on the sides.

Vertical Milling Machine

Flat End Mill: Flat end mill is also called square end mill. These cutters have multiple functions in vertical milling machines. Typical operations include plunging, face milling, side milling, grooving and counterboring.

Ball-end mill: Ball-end cutters have a hemispherical bottom face. The purpose of a ball-end mill in a vertical mill is to produce rounded grooves. Grooves for metal bearings in machines are often made with a ball-end mill.

Chamfer Mill: A chamfer mill is used to finish the edges of the workpiece. It produces rounded corners in chamfers and bevels.

Twist Drill: Twist drills have multiple flutes that converge at a single point. The number of flutes varies from two to three to four. The purpose of a twist drill is to cut metals and wood.

Reamer: Reamers are used to enlarge holes previously drilled with a drill or boring machine. Precision reamers provide a small enlargement of all but a high degree of accuracy. Non-precision reamers can give a larger enlargement but with low accuracy. Reaming is also used to improve the surface finish of a hole.

Tapping Mill: A tapping mill or tap is used to create threads in a hole. In general, tapping is preferred for holes that pass completely through a workpiece. Tapping can provide a high-speed operation compared to thread milling.

Extending Milling Tool Life

Tool life is a critical parameter when it comes to milling cutters. Understanding tool life and how to extend it can result in significant savings in milling costs and waste.

What is tool life?

Tool life is the period of useful operation of a cutting tool. It is the life of a tool from the time it is first used to the time it no longer produces the desired results. It is important to note that tool life is not limited to tool breakage. A tool can be at the end of its life even if it has not broken, but has stopped producing the desired cutting results. At the end of tool life, you must replace the tool.

Tool life is a major factor in the cost of operating a milling machine. Low tool life means more tool changes. This can significantly increase the cost of ownership of a milling machine.

What is tool wear?

Tool wear is the degradation of the cutting tool due to operation. Tool wear occurs in all machining operations. The rate of wear can vary depending on the tool material, the build quality and how the operator uses the machine.

All tools are supplied with an estimated tool life. However, tool usage varies widely from application to application. Therefore, exact tool wear and tool life cannot be determined in advance. The operator must inspect the tool periodically to analyze wear. The operator can determine if more tool life is available by examining the tool wear.

What is cutting fluid?

Cutting fluid is a type of compound that reduces tool wear and extends tool life. It is commonly used when milling metal materials. Cutting fluid is known by many other names such as lubricant, coolant, cutting oil or cutting compound. Cutting fluid provides several benefits:

Heat dissipation: Milling metal generates a lot of heat. This heat causes the tool to wear faster. The cutting fluid absorbs this heat and lowers the tool temperature, reducing tool degradation.

Lower friction: Cutting fluid reduces the coefficient of friction between the metal and the cutting tool. This results in a faster cutting process and further reduces tool wear.

Chip removal: Chips often stick to the cutting surface due to high heat. This impedes the movement of the cutting tool and increases tool wear. Cutting fluid prevents chips from interfering with the process and prevents chips from fusing with the work surface.

Types of Cutting Fluids

There are many different types of cutting fluids used in the milling process. These types are

Liquids: Liquids are the most common type of cutting fluid. There are three classes of liquid cutting fluids: mineral, semi-synthetic, and synthetic. Mineral oils are petroleum-based cutting fluids. Synthetic fluids are water-based compounds.

Paste: Liquid cutting fluid is not suitable for all applications. Therefore, cutting fluid is also available in paste and gel forms.

Aerosol: Aerosol cutting fluid is sprayed onto the work surface. These are not highly preferred due to the health hazards to employees.

Air-based: Air-based cutting fluids use gases such as nitrogen. These are new and advanced types of cutting fluids. They are typically used when milling tough materials such as titanium and inconel. It can result in ten times longer tool life.

What are the key parameters for milling?

The important parameters for the milling machining process are

Feed Rate: Feed rate is the relative speed of movement between the cutting tool and the workpiece during the CNC milling process. This value is measured in millimeters per minute (mm/min) or inches per minute (IPS or in/min).

Depth of cut: Depth of cut is the vertical thickness of material removed in a single pass. It can be measured in inches or millimeters. A higher depth of cut results in a slower cut and increased tool wear.

Spindle Speed: Spindle speed is the speed at which the tool (or spindle) rotates. It is measured in revolutions per minute (RPM). A higher spindle speed results in a faster cut and a higher rate of material removal.

Axial depth of cut: The axial depth of cut is the length of the cut measured axially in the direction of the cutting tool. This value is also the width of the cut in a single pass. The axial depth of cut determines the chip thickness.

Radial depth of cut: The radial depth of cut is measured along the radius of the cutting tool. This value is also the diameter of the cut on the workpiece. It determines the deflection of the cutter.

Tool Diameter: The tool diameter is the diameter of the particular cutter. It can be measured in inches or millimeters. The tool diameter determines the dimensions of the cut, the cutting forces, and the chip evacuation.

Cutting Speed: The cutting speed is the speed at which the tool moves along the workpiece. This value is obtained by multiplying the circumference of the tool by the spindle speed. This value is measured in surface feet per minute (SFM) or meters per minute (m/min).

Tool Overhang: Tool overhang is the distance between the toolholder and the tool edge. This distance can be considered the functional length of the tool. A larger tool overhang increases vibration, reduces stability and increases tool wear.

Coolant Flow Rate: The coolant flow rate is the rate at which the cutting fluid flows to the work surface. The coolant flow rate is adjusted according to the cutting speed and feed rate.

Tool Coating: Special coatings are applied to milling tools to improve cutting quality and reduce tool wear. Common tool coatings include diamond-like carbon (DLC), titanium nitride (TiN), and titanium aluminum nitride (TiAlN).

Stepover: Stepover is the distance between two back-to-back passes during milling. Too little stepover can result in interfering cuts, leading to poor accuracy and errors.

Ramp Angle: Ramp Angle is the angle of contact between the cutter and the workpiece as the cutter enters the workpiece. This angle is used in ramping operations.

Acceptable Milling Standards

Understanding milling standards can help you know what to expect from your milling operation.

Machining Tolerance

Machining tolerance is the deviation of the milled cuts from the intended cuts in the blueprint. A tighter tolerance means a more accurate operation. CNC milling machine tools can produce parts with tolerances as low as ± 0.005″ (about 0.13 mm). This is a very low value that gives the milling process high-precision features.

For plastics, the tolerance is higher at about ± 0.010″. This is due to the effect of plastic deformation and heat.

Minimum Wall Thickness

Milling parts require a minimum wall thickness. Walls thinner than this value can often collapse during milling or later machining. The minimum wall thickness is 0.5 mm for metals and 1.0 mm for plastics.

However, it is recommended to exceed this value to allow for some margin of error. The recommended values are 0.8mm for metals and 1.5mm for plastics.

What are the benefits of milling?

There are many advantages that milling has to offer over alternative manufacturing processes. These advantages are

Versatile: Milling is a very versatile process. It can create a wide range of shapes on many different types of materials. Alternative manufacturing processes such as 3D printing are limited in terms of materials.

Precision: CNC milling is one of the most precise manufacturing technologies available. It is the process of choice in fields such as aerospace, where precision is paramount.

Efficiency: Milling is very efficient. CNC milling can produce parts at a rapid pace suitable for mass production.

Quality: Milling is a high quality process. Parts produced by milling typically do not require secondary surface finishing.

Automation: Milling is often integrated with CNC machine tools. This automates the entire process, reducing labor requirements and increasing production rates.

Cost-effective: The high production rate and low labor costs result in a very cost-effective operation.

Consistent: The high precision of milling produces very consistent parts. This is important for producing commercial parts where repeatability is key.

Machining hard material: Milling can easily machine hard materials such as titanium and Inconel. These materials are difficult to machine with alternative technologies.

Common milling materials

Milling can machine a wide range of workpiece materials. Some common materials that can be milled include

Metals

Metals are the most common class of materials that can be machined. Milling can produce parts from any type of metal. This includes hard metals such as titanium and soft metals such as copper. Some of the metals and alloys best suited for milling are

Aluminum

Stainless steel (all grades)

Carbon steel

Copper alloys

Nickel

Chromium

Bronze

Plastics

Milling of plastic parts is common for high precision parts or to produce parts in large quantities. When milling plastics, it is important to monitor the temperature. This is because plastics can deform in the presence of heat. Common types of plastics machined are

ABS

Nylon

Peak

POM

Polycarbonate

Composite Materials

Composite materials are common in industries such as aerospace due to their extreme physical properties. These physical characteristics also make them difficult to machine using conventional methods. However, milling can easily machine these materials. Commonly milled composites are

FRP

Carbon fiber

Metal matrix composites

Polymer matrix composites

Ceramic matrix composites

Woods

Milling can be used on a wide variety of woods without causing adverse effects. Milling of wood is a common process in the furniture industry. These woods include

Hardwood

Softwood

Plywood

Ceramics

Ceramics can be difficult to machine due to excessive chipping and brittle nature. To solve this problem, ceramics are milled prior to final sintering. Commonly milled ceramics are

Alumina

Macor

Aluminum Nitride

Boron Nitride

Alumina Silicate

Glass

Graphite

Fused Quartz

Other materials

In addition to the above materials, the milling process is also commonly used for materials such as

Rubber

Foams

Stones such as marble and graphite

What materials are not suitable for milling?

Most materials can be machined by milling. However, certain materials can present additional challenges to milling. Here are some of those challenging materials:

Brittle materials: Brittle materials have the problem of excessive chips. These chips often fly around the work area creating hazards. There is also the risk of material cracking.

High hardness materials: High hardness materials have poor machinability. Milling these materials causes rapid tool wear. This results in frequent tool changes and high milling costs.

Reactive materials: Milling can significantly increase the temperature of the work surface. Therefore, cutting materials with a reactive nature becomes very challenging.

Is milling expensive?

Yes, CNC milling can be expensive due to the high cost of equipment. Good quality CNC mills can start at around $50,000 and go astronomically high. The cost of ownership for milling is not high. It can start at about $40 per hour.

Therefore, the most cost effective way to mill parts is to outsource the milling process. Most manufacturers choose 3ERP to handle all machining operations. The parts can be created from the exact blueprint you provide. This results in a very affordable operation without having to invest in the equipment itself.

Is the milling process safe?

Milling machines are capable of cutting the toughest materials in existence. These cutters can easily penetrate human body parts, making it very unsafe. Therefore, a router should only be operated by a trained operator. In addition, it is essential to use safety equipment and a machine with all guards.

What are the hazards of milling?

Common milling hazards include

Sharp cutters: Cutters are very sharp and rotate at extreme speeds. The cutter or any other rotating machine part should never be in contact with a person during operation.

Chips: Milling removes unwanted material in the form of chips. These chips travel at high speeds and can puncture the skin or sensitive organs such as the eyes.

Noise: Milling, like other industrial equipment, produces high levels of noise. It requires proper noise-cancelling ear protection.

Heat: The process generates high temperatures that should not come into contact with people. The parts may retain the high temperature for some time after the operation has stopped. Handling with gloves is essential.

Electrical Hazard: Machines use extremely high voltage. It is important to cover all electrical parts with guards and label them as electrical hazards.

How long does the milling process take?

The milling process takes from a few seconds to a few minutes. The movement of the cutter is extremely fast. Most of the time is spent loading and unloading the part.

Common milling problems

There are certain problems that may occur during the milling process. These are

Chatter: Chatter is a common problem when the tool is not properly mounted. Chatter is also typical when milling corners. Chatter causes high vibrations that break the tool and cause defects in the parts.

Tool wear: Some tool wear is unavoidable in milling. However, not optimizing the milling process can accelerate wear and require frequent tool changes.

Workpiece deformation: The high heat and cutting force can sometimes cause workpiece deformation.

Chip evacuation: Milling requires a proper chip evacuation strategy. Otherwise, the chips will continue to cut with the tool.

Tool collision: Tool collision occurs when the dimensions are not accurately considered.

Conclusion

Milling has been the most common industrial process since its inception over 200 years ago. The wide variety of milling operations can produce parts of any desired shape. This makes milling the operation of choice, especially in metalworking. Contact MY Prototyping for an accurate quote on how much milling will cost you for your next project.

Frequently Asked Questions (FAQs)

Here are answers to some common questions about milling:

1. What is the golden rule of milling?

The golden rule in milling is: thick in, thin out. The operator should aim for thick chips as the tool enters the workpiece. The operator should aim for thinner chips as the tool moves in and out of the workpiece. This results in a stable milling operation.

2. How accurate is milling?

Milling is one of the most accurate machining processes. It can provide tolerances as small as ± 0.005″.

3. What is the difference between milling and turning?

There is a big difference between milling and turning. Milling uses a rotating cutting edge against a stationary surface. Turning, on the other hand, uses a stationary cutting tool against a rotating surface.

4. What is the difference between milling and 3D printing?

There are many differences between milling and 3D printing. Milling is a subtractive manufacturing process. On the other hand, 3D printing is an additive manufacturing process. Milling works on all materials, but 3D printing only works on certain plastics.

Disclaimer of Warranty

The contents of this website are for informational purposes only. MY Prototyping makes no representations or warranties of any kind, express or implied, as to the accuracy, completeness or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be supplied by third party suppliers or manufacturers through MY Prototyping’s network. Buyers seeking instant quotes for parts are responsible for defining the specific requirements for those parts. Please see our Terms and Conditions for more information.