Injection Molding Service

Custom injection molding services for prototypes and on-demand production parts. Get a free injection molding quotation and design feedback within hours.

No minimum order quantities

Rapid Tooling Production as fast as 2 weeks

ISO 9001:2015 certified

24Hrs

Instant Quotes

1 pc

MOQ

24/7

Engineer Service

99.5%

On time Delivery

14+

Years in Business

- Home

- injection molding

MY Custom Injection Molding Services

Discover the excellence of MY Prototyping’s injection molding services in China. We expertly mold plastic parts, considering size, complexity, and volume specifications. Our state-of-the-art machines, ranging from 30t to 1800t, guarantee precision in every design. Enjoy on-demand prototypes and efficient production runs. Avail of a complimentary design consultation for each injection molding order. Experience swift turnarounds with lead times as brief as 15 days. Elevate your projects with our custom injection molding expertise.

Rapid Injection Mold

Swift and efficient manufacturing from prototype to production, reducing costs and delivering high-quality molded parts. Elevate your project speed with our expertise in rapid injection molding innovation.

Injection Molding

Elevate your production with our plastic injection molding expertise. Top-quality, versatile, and efficient – experience innovation at its best.

Insert Molding

Seamlessly integrate components for cost-effective durability. Elevate your manufacturing capabilities with our expert insert molding innovation.

Overmolding

Fusion of durability and design flexibility. Our overmolding services redefine product excellence with seamless material integration. Experience innovation at its best.

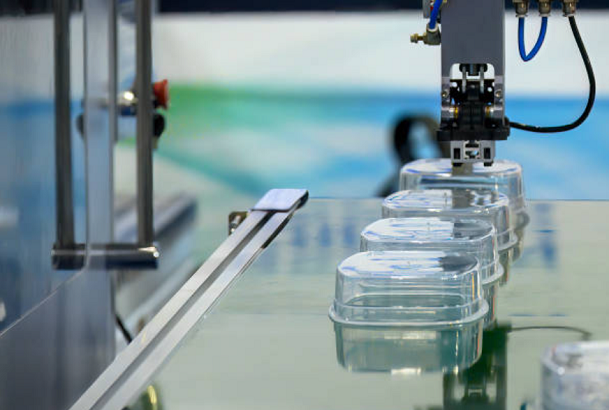

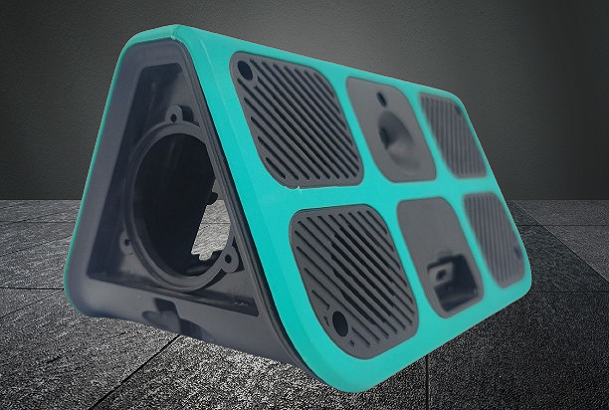

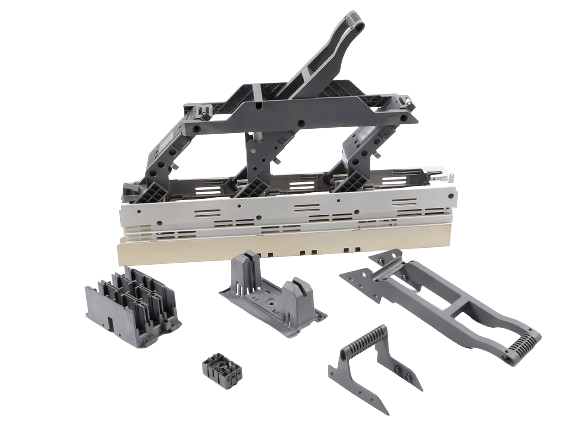

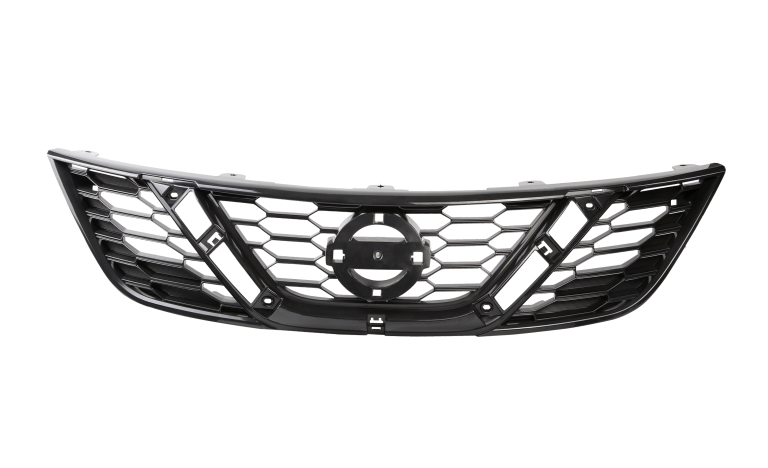

Gallery of Injection Molding Parts

Immerse yourself in MY Prototyping’s extensive gallery, showcasing completed injection molded parts. Gain confidence that we can bring your injection molding project to life with precision according to your strict specifications.

From Prototyping to Mass Production

Swift and Cost-Efficient Rapid Injection Molding

Get 1K-100K units quickly at a low cost using our rapid injection molding. With aluminum or steel molds, we ensure a fast turnaround, addressing production challenges and reducing time-to-market. Speed up your success with us.

Precision in Mass Production mold

Elevate your output with low volume injection molding—produce 100K-1M units using resilient steel molds for high-quality, consistent results. Optimize your production with us.

MY Prototyping Injection Molding Capabilities

| Standards | Description |

|---|---|

| Maximum Part Size | 1200×1000×500 mm; 47.2×39.4×19.7 in. |

| Minimum Part Size | 1×1×1 mm; 0.039×0.039×0.039 in. |

| Part to Part Repeatability | +/- 0.1 mm; +/- 0.0039 in. |

| Mold Cavity Tolerances | +/- 0.05 mm; +/- 0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Machines Available | Single cavity, multi-cavity, and family molds, 50 to 500 press tonnage |

Materials for Injection Molding

These are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.

Tooling Materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

ABS HDPE LDPE PP

PPA PS POM PC

PU Teflon (PTFE) Nylon

PC PMMA PA PEEK

PET

Our Injection Molding Processes

See how we process your orders, from quotation to tooling, as our machines and efficient team ensure you receive your molds and parts within the scheduled lead time.

Design Submission

Kick off the process by uploading your 3D model files online, or you could email us directly. Seamlessly supports various file formats such as [.STP], [.STEP], or [.STL], ensuring compatibility and ease of use.

Instant Quote & DFM analysis

Upon submitting your project, an immediate quote will be provided. Our sophisticated algorithms conduct a thorough analysis of your design, pinpointing potential manufacturability issues and fine-tuning for optimal printing efficiency.

Order confirm & Deposit

Client confirm the price and order for us. Some deposit we use for formal DFM report, mold design and purchase the plastic injection mold steel material. We have very strictly process for injection mold project. We care about.

Project Kick off in MY Prototyping

Once we receive the client’s order confirmation, we organize interior team to study client’s part design, and emphasize the client’s request , remark the plastic part and plastic injection mold important points, the risk we need avoid and the back up solution. To make sure the plastic part quality.

DFM & Mold design confirmation

Before project kick off, we confirm the team member responsible for different position. After project kick off, the designer need supply the DFM report. We discuss with client and after the confirmation, we could submit the mold design, only the mold design confirmed by clients, we could start the next step.

Steel cut & mold manufacture

Client confirm the mold design, we start to cut the steel. It takes 2-3 working days to purchase, and we start the plastic injection mold manufacturing then, the same time, MY prototyping send the mold time schedule to clients. It usually takes 20-45days to get the T1 samples, depends on the mold size and mold structure.

T1 sample and mold maintenance

Clients could clear about we need to do at each step from the mold time schedule. After first mold try out, we would send T1 samples to client for confirmation, and MY prototyping supply the mold maintain solution. After 2-3 times maintenance, we’ll get the final good assembly plastic parts, during this step, we help clients deal with the surface finishing.

Final sample confirmation

We ship the final samples to clients, clients need confirm the final samples including the surface treatment to MY prototyping. If client have the special request of the packaging, need tell us and confirm also. We start the plastic part production according to client’s quantity.

Part production &QC & delivery

At MY prototyping, we package and QC the part for first time, during plastic part production.Once products manufacturing finish, we ship the parts to warehouse, we arrange the QC team for second time checking. We’ll arrange the the part delivery according to our delivery term. And we could freely supply client prepare everything if client has their own forwarder to ship.

Why Choose Us for Injection Molding

Instant quote within 24Hrs

Experience the convenience of receiving an instant quote within 24Hrs. Our efficient and streamlined process ensures a swift response, allowing you to quickly proceed with your project without delays. At MY prototyping, we prioritize efficiency and responsiveness to meet your needs promptly.

Consistent High Quality

Owing ISO certified factories, conducting in-process inspections and dimensional verification after production, guarantee the custom molded parts consistency regardless of the complex shape with high precision.

Fast and Reliable Delivery

Benefit from our robust manufacturing capacity at MY Prototyping, ensuring swift turnaround for Injection mold parts. Our diverse shipping options further guarantee on-time delivery, eliminating typical hassles in the process.

Professional Engineering Support

Wherever you are, access our 24/7 engineering support year-round. Our seasoned engineers are ready to offer the most suitable solutions for your part design, material selection, surface finishing, and lead time considerations.

Explore SPI Finishes for Injection Molds

Dive into our range of SPI finishes for plastic injection molds. Specify VDI textures by detailing your requirements when submitting a quote on our platform.

| SPI Finish Standards | Surface RA Roughness | Finishing Method | Textured | Steels Recommended |

|---|---|---|---|---|

| SPI A1 | 0.012 to 0.025 | 6000 Grit Diamond | Super High Glossy finish | S136 (54HRC) 8407(52HRC) |

| SPI A2 | 0.012 to 0.025 | 3000 Grit Diamond | too High Glossy finish | S136 (54HRC) 8407(52HRC) |

| SPI A3 | 0.05 to 0.10 | 1200 Grit Diamond | Normal Glossy finish | S136 (300HB) or 718H |

| SPI B1 | 0.05 to 0.10 | 600 Grit Paper | Fine Semi-glossy finish | 718H |

| SPI C1 | 0.35 to 0.40 | 600 Grit Stone | meticulou smatte finish | 718H |

| SPI D1 | 0.80 to 1.00 | Dry Blast Glass Bead | Satin Textured finish | 718H |

Understanding SPI Mold Classifications

We follow the five standard categories of SPI mold classifications, ranging from Class 101 to 105. This ensures clear alignment of expectations for both customers and suppliers.

| Mold Class | Production Level | Cycles | Applications | Tolerance | Cost | Lead Time |

|---|---|---|---|---|---|---|

| Class 105 | Prototype Testing | Under 500 cycles | Prototype testing | ± 0.02mm | Fall within low to moderate price ranges | 7-10 days |

| Class 104 | Low-volume Production | Under 100.000 cycles | Good for limited-production parts with non-abrasive materials | ± 0.02mm | Inexpensive to produce a very limited number of product prototypes | 10-15 days |

| Class 103 | Medium | Less than 500K cycles | For low to medium-production parts | ± 0.02mm | Fall within common price ranges | 10-15 days |

| Class 102 | Medium to high | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm | Fairly high price and made with materials of high quality | 10-15 days |

| Class 101 | Extremely high | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm | Highest price and made with only the highest quality materials | 10-18 days |

Injection Molding for Various Applications

Automotive

Robotics

New energy

Home Appliance

Communication

Start a new project production today!

FAQs about Injection Molding Service

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Tolerances are crucial in injection molding; without proper specification and control, assembly issues can arise. At MY Prototyping, we adhere to the ISO 2068-c standard for molding tolerances, but can accommodate tighter specifications if needed.

We have no minimum order requirement. However, larger quantities will yield more competitive pricing.

Once an order is placed, mold design and creation typically take around 35 days, with an additional 3-5 days for the production of the molded parts.

The cost of our services varies based on several factors such as component size, mold complexity, number of cavities, material type, and post-processing requirements. We provide quotes after analyzing these factors on our platform.

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …