Finishing Services

Elevate the aesthetics and functionality of your parts with our high-quality surface finishing services, applicable to various manufacturing processes. Whether it's metal, composites, or plastic, we deliver top-notch finishing to bring your dream prototype or part to life.

No minimum order quantities

Get rapid quotes within 24 hours

ISO 9001:2015 certified

24Hrs

Instant Quotes

1 pc

MOQ

24/7

Engineer Service

99.5%

On time Delivery

14+

Years in Business

Excellence in Surface Finishing: Our Portfolio

Explore our exceptional part finishing services, where our expert teams specialize in plastic, composite, and metal surface finishing. With state-of-the-art machines and infrastructure, we bring your ideas to life with precision and excellence.

Anodizing

Polishing

Bead Blasting

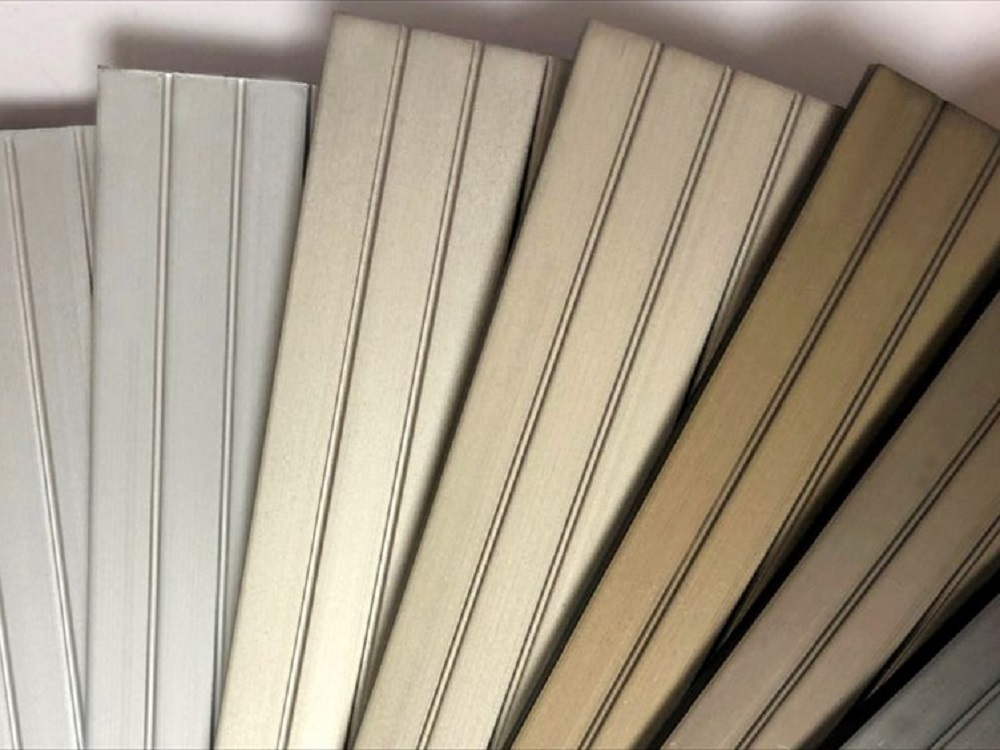

Brushing

Powder Coating

Black Oxide

Electroplating

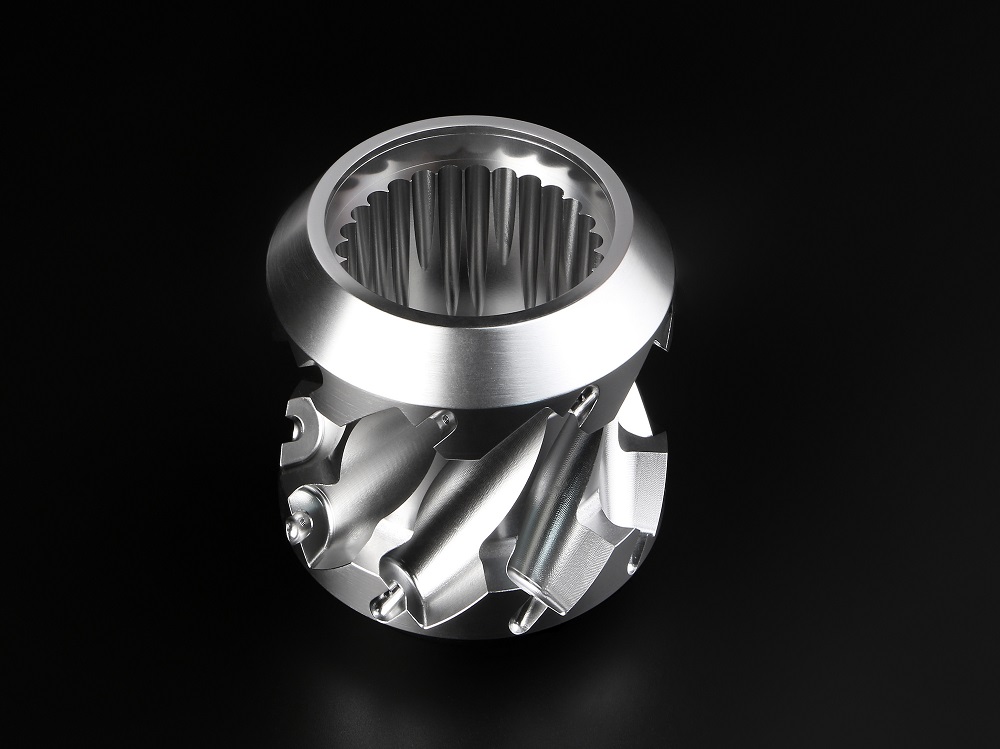

As-machined

Explore Our Surface Finshing

Dive into our range of SPI finishes for plastic injection molds. Specify VDI textures by detailing your requirements when submitting a quote on our platform.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| PowderCoating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | satin |

| Black Oxide | Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance. | Steel, Stainless Steel | Black | Smooth, matte |

| As-machined | The standard finish for our parts, the “as machined” finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburs parts cleanly. | All materials | N/A | Stain |

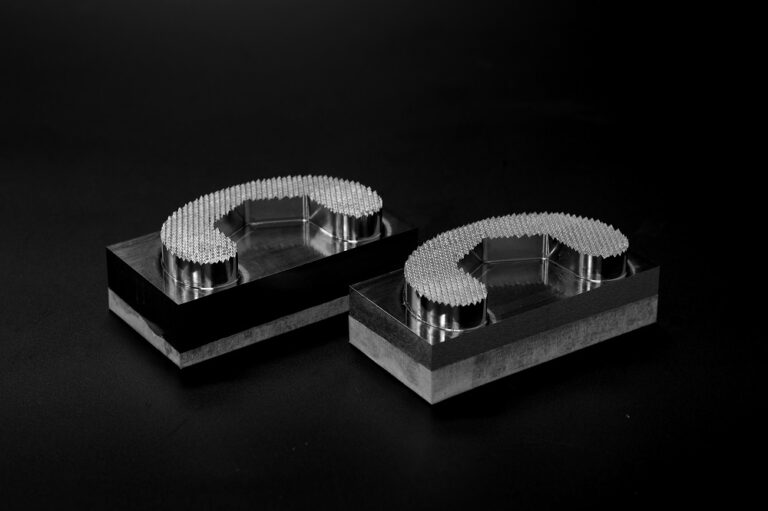

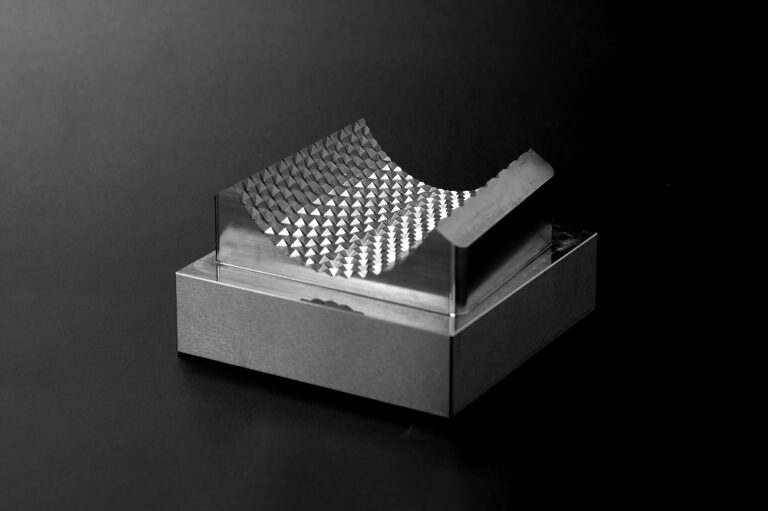

Gallery of Cosmetic Surface Finish

Explore our gallery featuring custom parts crafted with meticulous precision and exceptional surface finishing techniques. Get a glimpse of our commitment to quality craftsmanship.

Work With Various Industrial Applications

With expertise in rapid prototyping and low-volume production, we’ve catered to diverse industries, including automotive, aerospace, consumer goods, medical devices, robotics, and beyond. Partner with us for tailored solutions across various industrial applications.

Automotive

Robotics

New energy

Home Appliance

Communication

Start a new project production today!

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …