Vacuum Casting Service

Experience reliability in prototyping and low-volume production with our vacuum casting service at MY Prototyping. We offer competitive pricing for highly detailed elastomer parts, ensuring excellent quality and faster turnarounds for your projects.

No minimum order quantities

Production Grade Quality

ISO 9001:2015 certified

24Hrs

Instant Quotes

1 pc

MOQ

24/7

Engineer Service

99.5%

On time Delivery

14+

Years in Business

Flexible and Economic Precision: Vacuum Casting Services

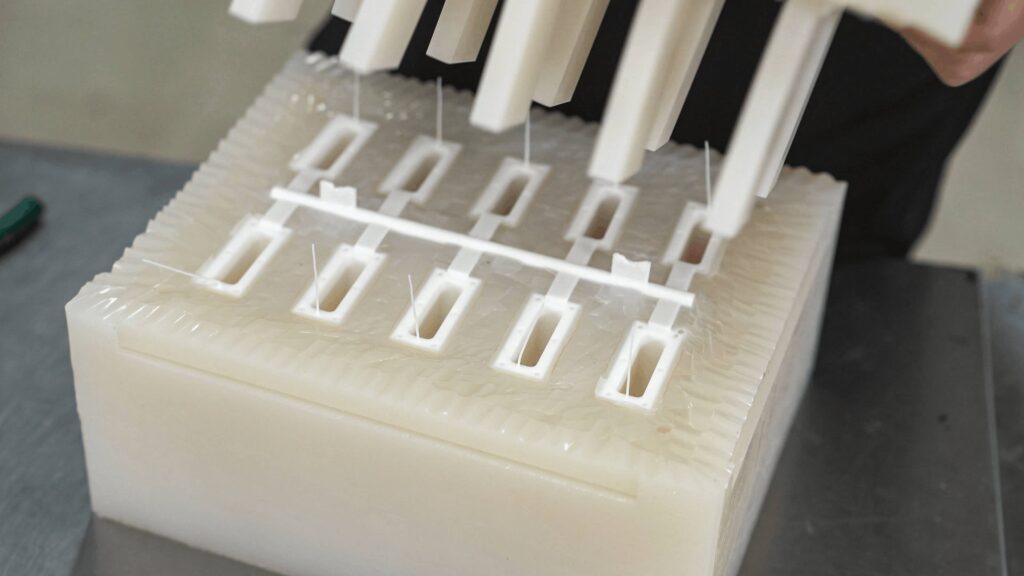

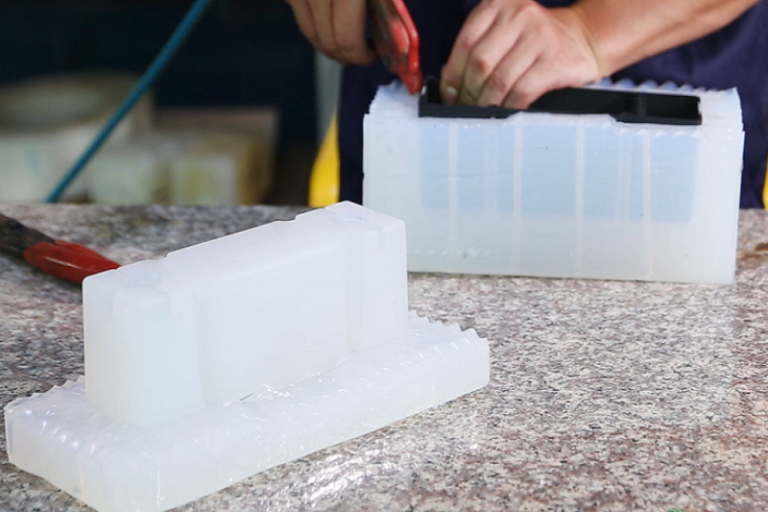

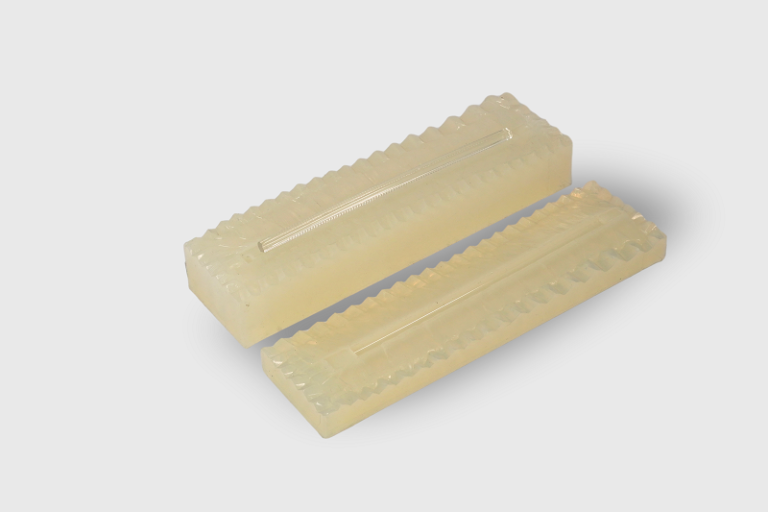

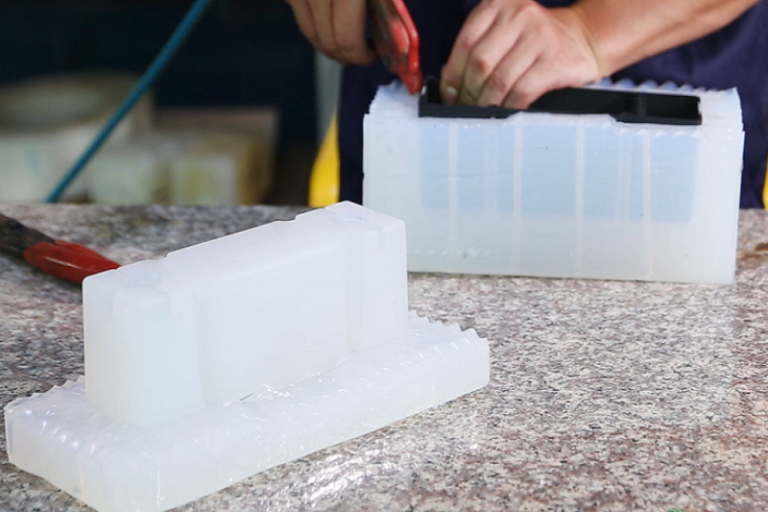

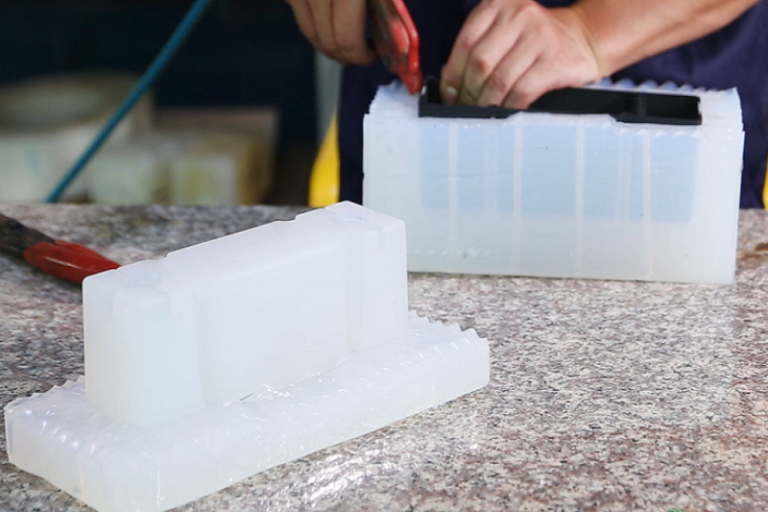

Experience flexibility and cost-efficiency with MY Prototyping's vacuum casting services. Our urethane casting seamlessly blends silicone molds and 3D printed master patterns for short-run, high-quality plastic parts. No need for expensive upfront investments—get top-notch prototypes and low-volume production parts with ease. Elevate your production with our innovative vacuum casting solutions.

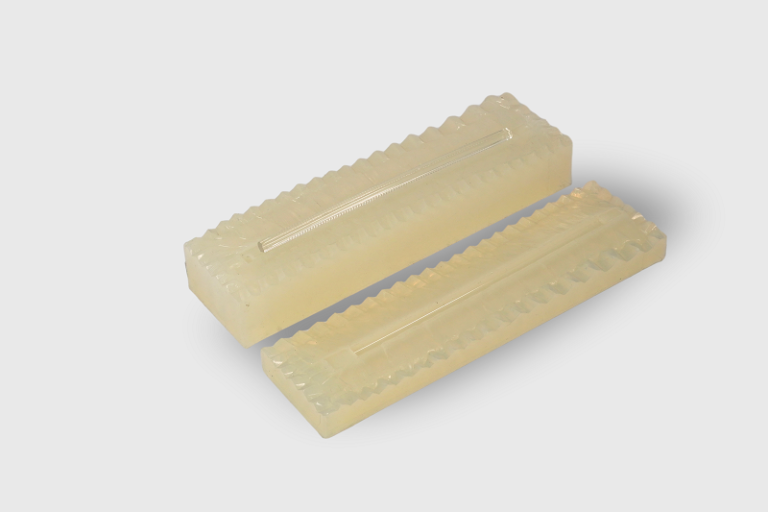

Gallery of Vacuum casting part

Vacuum casting parts are excellent options for custom and first-run production. You can cost-effectively test product quality before starting full-scale production.

Vacuum casting advantages

Rapid prototypes

The vacuum casting process involves low-cost tooling to ensure a more accessible and cost-effective way of creating prototypes. Create quality prototypes with various materials and design changes. Test your designs easily and get them ready for functional testing.

Markekting test

We help you create vacuum casting products ideal for market and consumer testing, concept models, and user evaluation. These parts come with high-quality finishes and end-use functionalities. Our urethane casting services allow you to incorporate changes quickly for further testing and market launch.

Explore our Vacuum Casting Service

MY Prototyping Vacuum Casting Capabilities

| Standards | Description |

|---|---|

| Standards Maximum Part Size | Description 1200×1000×500 mm; 47.2×39.4×19.7 in. |

| Standards Minimum Part Size | Description 1×1×1 mm; 0.039×0.039×0.039 in. |

| Standards Part to Part Repeatability | Description +/- 0.1 mm; +/- 0.0039 in. |

| Standards Mold Cavity Tolerances | Description +/- 0.05 mm; +/- 0.002 in. |

| Standards Available Mold Types | Description Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Standards Machines Available | Description Single cavity, multi-cavity, and family molds, 50 to 500 press tonnage |

Why Choose Us for Vacuum Casting

Instant quote within 24Hrs

Experience the convenience of receiving an instant quote within 24Hrs. Our efficient and streamlined process ensures a swift response, allowing you to quickly proceed with your project without delays. At MY prototyping, we prioritize efficiency and responsiveness to meet your needs promptly.

Consistent High Quality

Owing ISO certified factories, conducting in-process inspections and dimensional verification after production, guarantee the custom molded parts consistency regardless of the complex shape with high precision.

Fast and Reliable Delivery

Benefit from our robust manufacturing capacity at MY Prototyping, ensuring swift turnaround for Injection mold parts. Our diverse shipping options further guarantee on-time delivery, eliminating typical hassles in the process.

Professional Engineering Support

Wherever you are, access our 24/7 engineering support year-round. Our seasoned engineers are ready to offer the most suitable solutions for your part design, material selection, surface finishing, and lead time considerations.

Vacuum Casting for Various Applications

Automotive

Robotics

New energy

Home Appliance

Communication

Start a new project production today!

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

November 18, 2024

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

November 1, 2024

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …

July 16, 2024